The design principles of chopper pumps have evolved over 60 years. New ideas and concepts have come to fruition from field experience in chopping and pumping an ever-widening variety of items.

As a result, chopper pumps are able to pump a large array of solids that make their way into effluent wastewater. In treatment plants, these chopper pumps have been a crucial asset for operators who rely on consistent, minimal maintenance solids-handling pumps in critical applications.

Chopper pump development

Development of the first chopper pump began in the late 1950s when Jim Vaughan recognized the need for better pumps in local dairy waste streams, according to a Vaughan Co. spokesperson.

The pumps of the time weren’t able to handle the manure, twine and animal bedding that cluttered the waste streams in the dairy fields. To solve the issue, Jim Vaughan designed a chopper pump to break down solids using a multiblade rotating impeller chopping against fixed shear bars at the suction opening. While this basic design is the foundation of chopper pumps, field experience has proven that a number of additional chopping features increase the pump’s ability to eliminate clogging and binding.

Treatment plant applications

Ongoing engineering and field testing found an effective use for these pumps in the handling of tough solids often found at modern treatment plants. Kent Keeran, recently retired chief engineer of Vaughan, explains that Vaughan chopper pumps chop materials inside the pump rather than in front of a typical nonclog impeller.

“We also employ a number of patented chopping features specifically designed to ensure that the entrance to the pump remains free of solids entering the pump, and to ensure that both the front and back of the impeller remain free of any material that could eventually cause clogging or binding between the impeller and volute,” he says.

Product design

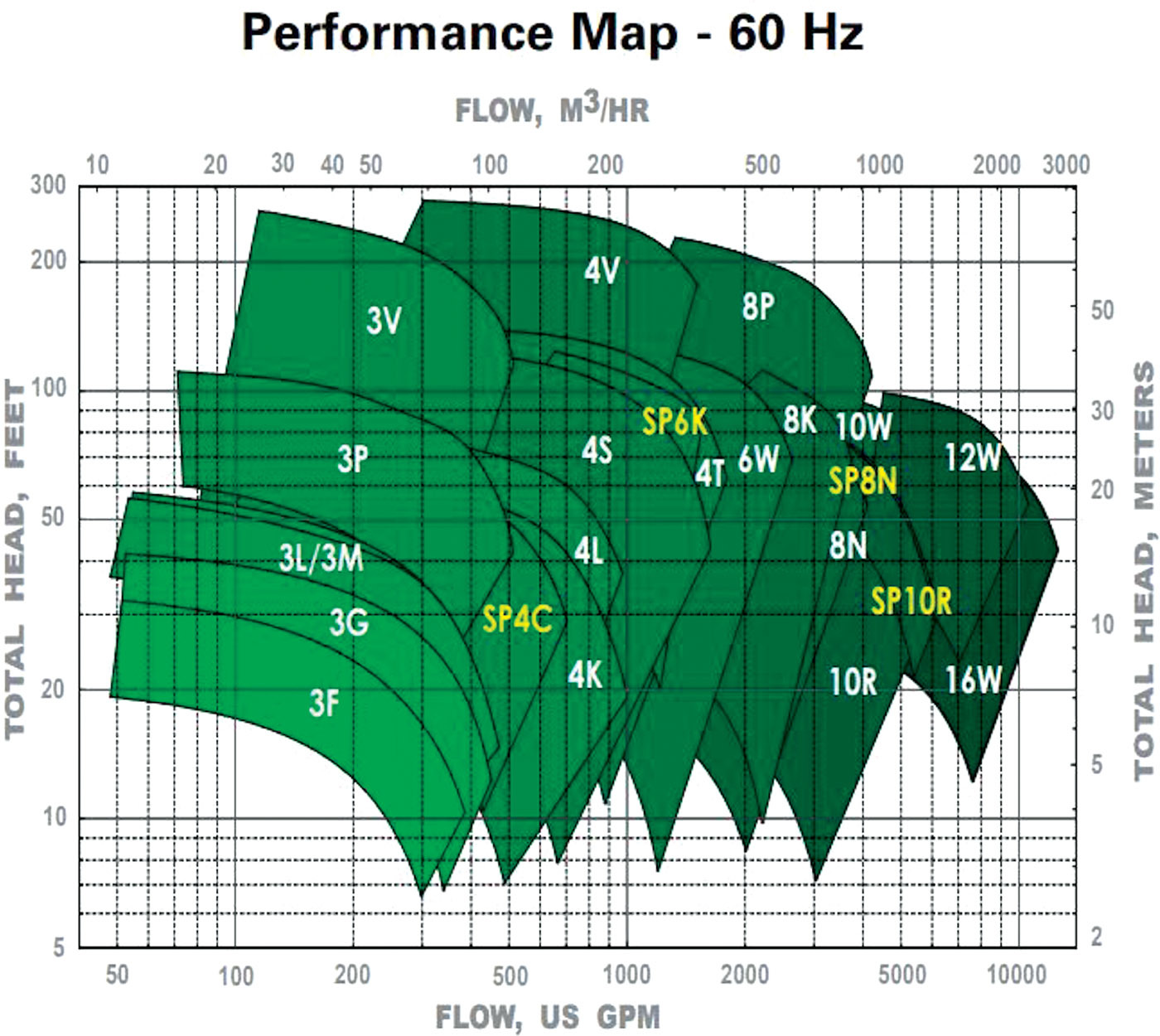

Vaughan has spent many years refining the use of computational fluid dynamics to improve the efficiency of existing pump designs and generate new pump models. Through careful validation of CFD simulations, Vaughan has been able to bypass physical performance testing of prototypes, which allows the engineering team to test hundreds of combinations of impeller blade shapes and pump casing designs to maximize chopper pump efficiency and reliability.

The key component in this process is the nearly 60 years’ chopping experience that forms the basis of knowledge, which allows the Vaughan team to accurately identify what impeller blade shapes and configurations work best for a chopper pump when considering how to run the CFD simulation process.

The final verdict for a successful chopper pump design can only be obtained in actual sewage treatment plant applications. “Vaughan Co. is very proud of the fact that through commitment to rigorous design and focused attention to customer feedback, all of the Vaughan chopper pump models operate successfully around the clock in the toughest applications found in today’s sewage treatment plants,” says a company spokesperson.

Vaughan Co. Inc. is a pumping and mixing equipment manufacturer located in Montesano, Washington, that provides products for both domestic and international businesses and municipalities. Vaughan focuses on producing quality pumps and mixers for tough applications within the municipal, industrial and agricultural markets. This focus on quality means the company takes time on each project to ensure that the pumps and/or mixers are properly sized for each installation.

888-249-2467 | info@chopperpumps.com | www.chopperpumps.com