Interested in Treatment?

Get Treatment articles, news and videos right in your inbox! Sign up now.

Treatment + Get AlertsSince the early ’90s, INVENT has been passionate about reshaping the sequencing batch reactor process for the biological treatment of municipal and industrial wastewater. By harnessing the advantages of batch processing and reactor behavior, upset events are unlikely to occur and boundary conditions stay constant while continuously treating wastewater.

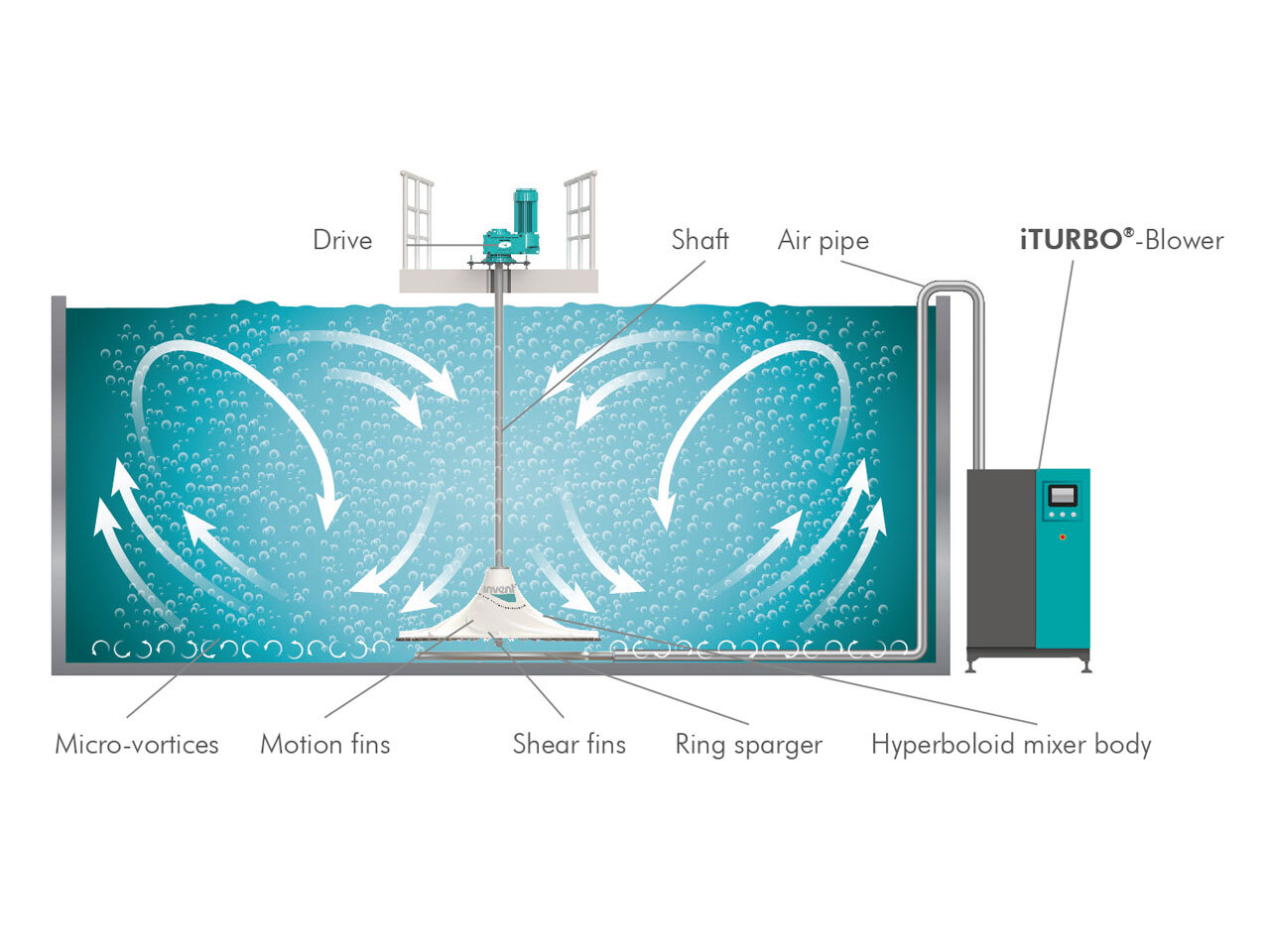

For the INVENT SBR design, the process heavily relies on the INVENT HYPERCLASSIC Mixing and Aeration System shown in the figure below. This system is the basis of every INVENT SBR, with the ability to effectively mix without aeration, but then aerate and mix simultaneously with no head-loss or fouling. The decoupled mixing and aerating make the INVENT HYPERCLASSIC system the ideal basis for the SBR and any other cyclic or intermittent process.

Schematic diagram of the HYPERCLASSIC Mixing and Aeration System

From the beginning, one of INVENT’s core values as a company is to deeply understand and analyze fluid mechanics and then design superior products for the water and wastewater industry around that understanding and analysis.

The main focus is on the essential processes of

- mixing

- mass transfer

- solid/liquid separation

Knowledge and analysis of fluid mechanical design heavily impacts and improves overall process efficiency and energy savings. This is how an entire line of advanced mixing systems, highly efficient aeration systems, high-performance decanters, and innovative filters has developed over time.

An additional core value is to thoroughly understand the treatment processes and to integrate a product that will be most beneficial to the client’s needs. This second core value inevitably led INVENT to a meticulous understanding of the detailed requirements of SBRs which resulted in an entire dedicated family of products including:

- Inflow distribution system

- HYPERCLASSIC Mixing and Aeration System

- iDEC SBR Decanting System

- SBR Surplus Sludge Retrieval systems

- iTURBO Blower high-speed turbo blower

- iFILT Diamond Disk Filter

- SBR control systems

With each product, INVENT has the ability to design, size and customize an entire plant to match the client’s individual needs and specifications.

INVENT’s experience and expertise can also be offered as an engineering and design package along with the product package. This complete SBR package is known as iSBR for conventional process design including all products required for design, integrated hardware and software systems, installation supervision, and startup and training supervision. INVENT can also include the additional design of the granular sludge process known as iGSR. These complete systems can be used for multiple applications including:

- Municipal wastewater treatment

- Industrial wastewater treatment

- Deammonification process

- Granular sludge processes

Compared to conventional systems in the market, iSBR is distinguished through improvements in:

- key equipment

- overall reactor design

- overall process design

- overall fluid mechanical design

Overall reactor design

The iSBR/iGSR reactor design is based on the idea of creating several individual zones in one reactor module located in series. This design can only work due to the unique features of the HYPERCLASSIC mixer/aerator which allows for the creation of an advanced process which:

- has a cascaded reactor design

- operates continuously

- is cyclic

This is known as the iC³-Process.

Cascaded reactor design

Each HYPERCLASSIC Mixing and Aeration System creates an individual zone which is cascaded over the entire reactor. These separate zones utilize the virtual wall effect created by multiple, side-by-side HYPERCLASSIC mixer/aerators. This allows for higher process flexibility since the system can run different modes and process parameters in each individual zone during the same cycle. For example, the first zone can act as a selector while the last zone is decanting.

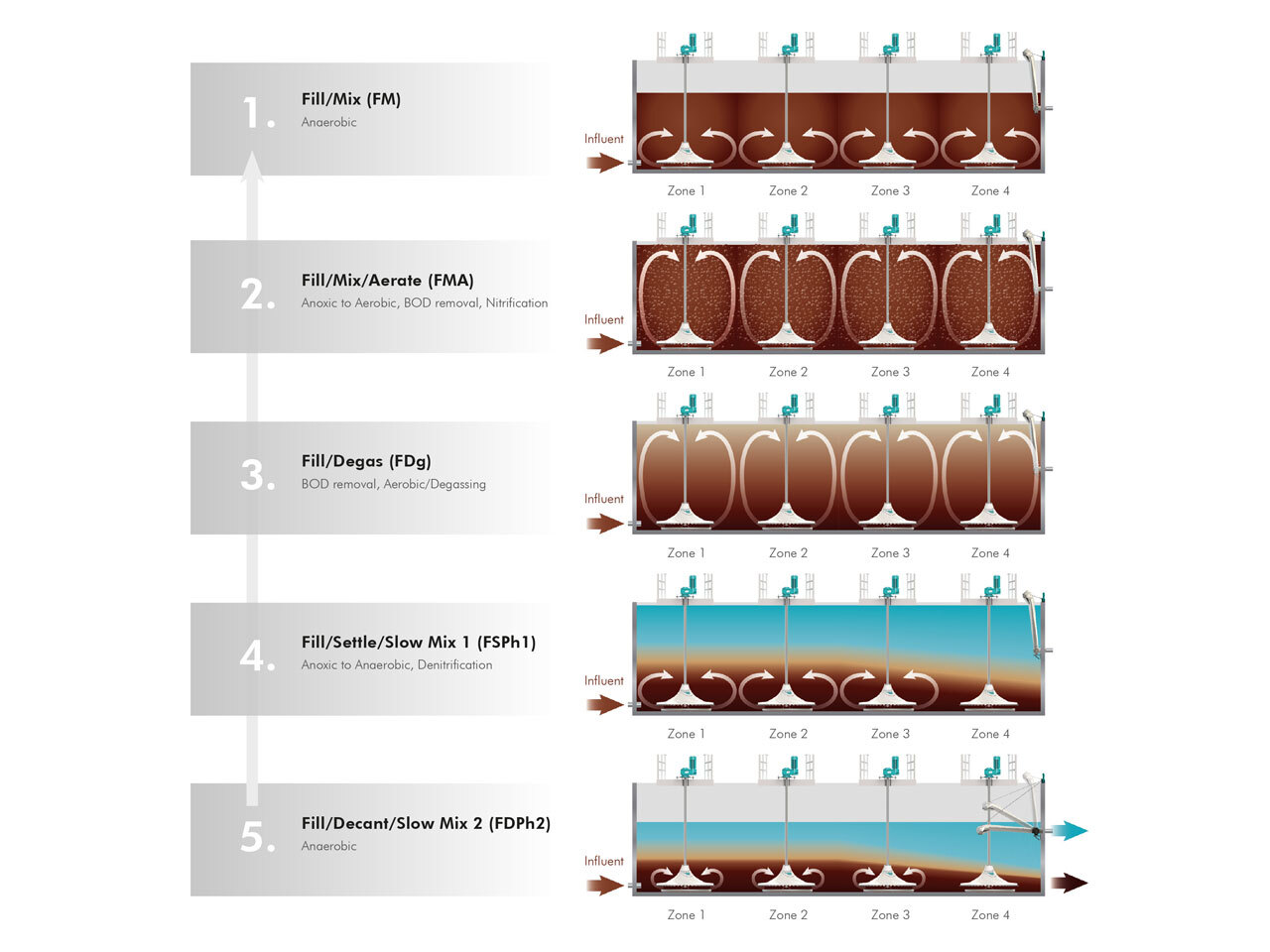

The individual steps of the iSBR/iGSR process

INVENT differentiates five different process phases, which repeat continuously and cyclically at different times in four different spatial zones (Zones 1 - 4). These zones are defined by the four different spatial zones of equal size in each SBR tank.

Overall process design

The continuous inflow and the division of the reactor into individual zones allows for an advanced process design shown in the figure below. The five basic cycle phases of the iSBR/iGSR process are shown schematically. After Phase 5, the cycle repeats itself and starts back at Phase 1.

Individual process design phases

1. Fill/Mix (FM)

In Phase 1, the HYPERCLASSIC Mixing and Aeration System operates at reduced speeds and provides mixing without aeration. Anaerobic conditions due to the continuous filling of wastewater are generated in Zones 1 and 2, while Zones 3 and 4 are mainly anoxic conditions. Subsequently, in Zones 3 and 4, the necessary anaerobic conditions are generated for a partial degradation of organic compounds and biological phosphorus removal, which may not be degraded solely under aerobic conditions.

2. Fill/Mix/Aerate (FMA)

During Phase 2 the aeration cycle, filling continues. The HYPERCLASSIC system operates at higher speeds while mixing and aerating. The system efficiently supplies the necessary oxygen for the BOD and COD removal and the nitrification process. Effective mechanical mixing during aeration is very important to maintain and ensure high α-values, to maintain high oxygen transfer rates, and to apply the necessary minimum shear stress on the granular biomass.

The HYPERCLASSIC system is a proven technology for aeration in bioreactors with granular sludge. Mechanical mixing during aeration is also desirable to avoid foaming and scum on the water surface. The enhanced mixing additionally ensures aerobic conditions and a minimized anaerobic core in the sludge flocs.

Due to the high oxygen demand resulting from the feed of fresh wastewater to Zone 1 of the iSBR, Zone 1 stays mainly anoxic during this phase.

3. Fill/Degas (FDg)

After the aeration cycle has been completed and the blowers are turned off, Phase 3 begins with a short period of rapid mixing at an increased speed of the HYPERCLASSIC system. With this phase, an effective degassing of the sludge flocs is achieved. This improves the sludge settling properties and avoids collection of foam on the water surface.

4. Fill/Settle/Slow Mix 1 (FSPh1)

Due to the anoxic conditions during the settling in Phase 4, denitrification processes take place in the first zones of the iSBR. The HYPERCLASSIC at the inlet of the basin operates at a low speed and gently mixes the fresh wastewater with the increasing sludge blanket at the bottom. At this low speed, the sludge blanket is maintained at the desired depth. The feed of raw wastewater into the sludge blanket creates, after a short anoxic phase, anaerobic conditions with biological phosphorus (Bio-P) release. Additionally, these anaerobic conditions promote the conversion of bCOD1 to rbCOD2 in the inlet zone (Zone 1) with anaerobic uptake of rbCOD and/or anoxic depletion at the same time. This minimizes aerobic uptake of rbCOD and creates the optimum biochemistry for aerobic granular sludge growth.

5. Fill/Decant/Slow Mix 2 (FDPh2)

During this last phase of the iSBR/iGSR process, the raw wastewater continues to flow into the sludge blanket in Zone 1, and the operation of the HYPERCLASSIC system at low speed continues. Anaerobic conditions necessary for biological phosphorus release are created within the sludge blanket.

In this final phase, the iDEC begins to withdraw the treated effluent (decant) without disturbing the sludge blanket. Also, during this phase, the excess sludge is removed from the settled blanket to maintain the required food to mass ratio for the process design. The waste sludge retrieval system prevents contamination of the effluent with sludge. As soon as the decanting cycle has been completed and the desired discharge volume has been withdrawn from the iSBR/iGSR, the decanter rises to its idle position above the water level and the process begins again at Phase 1.

iSBR/iGSR Benefits

Continuous flow operation

The INVENT iSBR/iGSR process uniquely combines the advantages of a batch operation with conventional continuous flow across the entire plant. This unique achievement makes large equalization basins in front of the biological reactors unnecessary and further reduces the overall footprint of the plant.

Modular design

The INVENT iSBR/iGSR systems are based on a modular design. The individual modules consist of either a single or a double train of HYPERCLASSIC mixer/aerators with however many necessary in series. The size of the base modules selected depends on the overall plant capacity which is required, the local conditions, and the overall design approach. Plant designs with several individual modules offer a higher flexibility and operational safety, and are customized for specific site conditions.

Reactor design

The iSBR/iGSR design is optimized for the SBR process and for the equipment used. It allows for maximum mass transfer, optimal reactor behavior, small overall footprint, high operational safety, efficiency, and performance, and consistently high-quality effluent. For the reactor design, a typical flow diagram of an iSBR/iGSR plant uses modern fluid mechanical simulation tools as well as dynamic simulation for the optimization of the overall process performance and specific load conditions.

Process design

The unique iSBR/iGSR process allows for aerobic granular sludge production under continuous flow conditions. This is only possible using a cascade of completely mixed stirred tank reactors created with the HYPERCLASSIC Mixing and Aeration System and the cyclic process conditions.

Unique equipment package

INVENT’s unique equipment package used in the iSBR/iGSR process is unlike any other approach on the market. The flow conditions created with the INVENT HYPERCLASSIC Mixing and Aeration System are unparalleled and make this process possible. The virtual wall effect ensures the desired reactor behavior, and the versatile mixing conditions allow for the safe granular sludge growth. The high aeration performance and quick response times facilitate reliable process control.

Comparing the HYPERCLASSIC system with standard membrane aeration systems still commonly used, the INVENT system has a significantly higher performance under process conditions (α- value), and most importantly, the system it does not lose efficiency and does not lose aeration performance over time.

The iSBR/iGSR process also benefits from the optimized product line:

- The iDEC-SBR Decanter allows for short decanting times.

- The high-efficiency iTURBO high-speed blower further reduces the energy consumption.

- The iFILT Diamond disk filter further reduces the amount of suspended solids in the effluent if locally required or if the water shall be reused, e.g. for irrigation purposes.

Having developed all these products in-house means that they have been optimally designed to function as a team, creating a complete and efficient system. For the purpose and the use in the INVENT iSBR/iGSR process, they efficiently work with each other to supply peak performance in each INVENT design.

Over the years, INVENT has been improving the sequencing batch reactor process and is now offering the advanced, proprietary iC³-Process in its iSBR/iGSR packages to selected clients.

Watch a video about the iSBR/iGSR process here