Interested in Treatment?

Get Treatment articles, news and videos right in your inbox! Sign up now.

Treatment + Get AlertsA common misconception for aerobic digestion is that the process must be aerated 100% of the retention time. In redefining this outlook, it has been found that cycling between mixing and mixing while aerating proves to be more effective and energy efficient. By having the ability to turn the air off and on, the system creates aerobic and anoxic phases allowing for further nutrient reduction, improved dewaterability, and increased volatile sludge destruction. This supports endogenous respiration and nitrification. Many different technologies exist for aerobic digestion, and often multiple types of equipment must be combined to achieve the cyclical process. Fortunately, there are systems that can perform decoupled mixing and aerating with only one device.

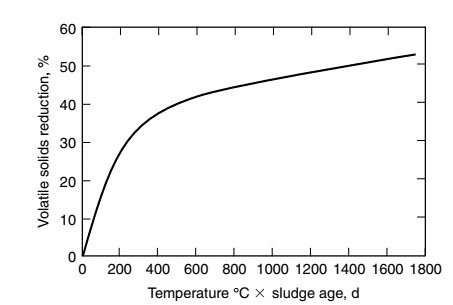

Aerobic digestion is a wastewater treatment process used to treat waste activated sludge or a mixture of sludges. Typical applications produce a sludge able to meet requirements for Class B biosolids, and retention times usually range from 40 to 60 days. Sludge destruction is primarily a direct function of sludge age and temperature shown in Figure 1 (Metcalf & Eddy, 2014).

Aerobic digesters can achieve thermophilic conditions which provide more rapid biochemical reactions and reduce the retention time 20 to 40 days typically. Thermophilic conditions can provide greater reduction in bacteria and viruses, meet Class A biosolid requirements when operating at 55 degrees C or higher, and lower energy requirements than conventional aerobic digestion. Although advantageous to aerobic digestion, this article will not discuss thermophilic conditions further and focus only on the traditional aerobic digestion process.

Aerobic digestion is the degradation of the organic sludge in the presence of oxygen. Oxygen is introduced in the basin or tank to allow the microorganisms in the sludge to convert the organic material to carbon dioxide and water, and the ammonia and amino species to nitrogen. Biochemical changes in an aerobic digester follow the subsequent equations:

Biomass destruction: biomass + oxygen → carbon dioxide + water + ammonium bicarbonate

Nitrification: ammonia + oxygen → nitrate + hydrogen + water

Overall equation: biomass + oxygen → carbon dioxide + water + nitric acid

Denitrification: biomass + nitrate → carbon dioxide + nitrogen + ammonia + hydroxide

Complete process: biomass + oxygen → carbon dioxide + nitrogen + water

Aerobic digestion is similar to the conventional activated sludge process but has longer retention times without a raw wastewater feed, i.e. nourishment for the microorganisms. When there is no new supply of organics for the microorganisms, they die and become nourishment for other bacteria in the tank, reducing the sludge organic solids concentration. This process is known as endogenous respiration. Aerobic digestion also has the ability to nitrify under certain conditions. Typical operations are controlled by pH; however, other parameters can be used to control the process.

Current technologies

Since both air and mixing are required for the aerobic digestion process, typical equipment may include coarse bubble aeration, jet aeration, surface aeration, and fine bubble aeration. To be able to do both, mixing and mixing while aerating, oftentimes multiple devices must be used.

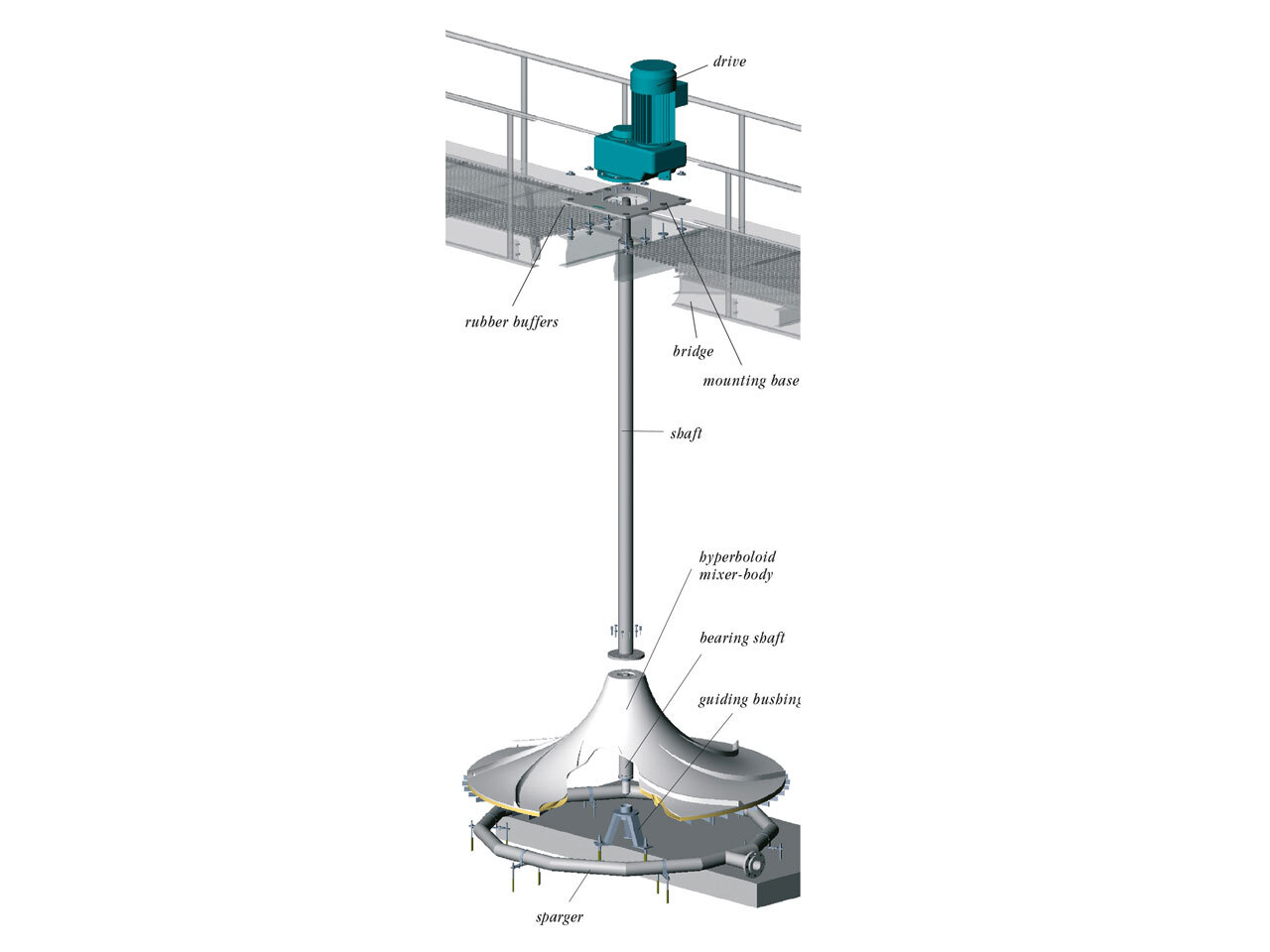

Technologies exist with the capabilities to perform mixing and mixing while aerating, eliminating the need for two different systems. For the ability to cycle between mixing and mixing while aerating, the INVENT HYPERCLASSIC Mixing and Aeration System has proven suitable for the application. The system provides the ability to mechanically mix and aerate for aerobic digesters. The air can be turned off while still mixing, creating anoxic conditions so that denitrification can occur. This system provides optimal control of a process that was once mostly inflexible and has significant advantages over other systems such as surface aerators.

The alpha value

With 2% or higher mixed liquor suspended solids (MLSS), mechanical mixing is required due to the viscosity of the liquid because air alone will not provide sufficient mixing. As the percent solids increase, there is a correlation with a decrease in the alpha value. The alpha value is the interference to oxygen transfer efficiency, and data indicates that there is strong correlation between fluid viscosity and oxygen transfer efficiency. In the article “Digester Aeration Design at High Solids Concentration,” research has shown that with fine bubble diffusers, the alpha value falls below 0.1 around 3% MLSS (Schoenenberger, Shaw, Redmon, 2003).

When the alpha value falls below 0.1, this can lead to unwanted anaerobic conditions causing odor and foaming, the HYPERCLASSIC Mixing and Aeration System provides higher alpha values as the mechanical nature of the device pushes oxygen deeper into the sludge flocs. The alpha value for solids ranging up to 5% can be around 0.27 for this mixing and aeration system. This results from the mechanical mixing, which allows for the distribution of air throughout the tank and system, providing a small to medium bubble for better oxygen transfer.

Cycling between mixing and mixing while aerating

Unlike the over-aeration from conventional continuous aerated mixing, a decoupled mixing and aeration system provides control over the entire aerobic digestion process through oxygen supply and/or mixing. Different parameters must be established to control the aerobic digestion process, both time and ORP (oxidation reduction potential) can be used to control the cycling between mixing and mixing while aerating alongside pH.

Since solids reduction is typically the main goal of aerobic digestion, changes in pH dictate the ability to destruct the biomass. When pH drops, alkalinity addition becomes necessary to combat poor dewaterability of the sludge. When the air is cycled off, alkalinity can be restored through nitrate destruction (denitrification). This off/on air cycle can now decrease the need for chemicals that are necessary for continuously aerated systems.

Nitrification can also be a main goal of aerobic digestion and is advantageous when ammonia in the digestate is of concern at the head of a plant. Starting with mixing and aerating, the biomass in the system destructs, creating carbon dioxide, water and ammonium bicarbonate. With air still being introduced into the system, nitrification can now happen — converting ammonium to nitrate, hydrogen and water. If air is always on, this continued process can drop pH and consume alkalinity. Now, introducing long periods of mixing only, the aerobic digester essentially becomes anoxic/anaerobic with zero oxygen throughout the entire basin. This cycle begins the denitrification process where nitrate combines with the hydrogen from the nitrification to form nitrogen and water, and in the presence of biomass, also creates carbon dioxide and ammonia. Denitrification restores pH by returning alkalinity to the system. With the pH restored, the aerobic digesters can turn air on, beginning the cycle over again. At the end of the process, the digestate now has up to 20% less ammonia returning back to the head of the plant.

The HYPERCLASSIC Mixing and Aeration System

By enabling the operator to have more control over the aerobic digestion process, plants have the ability to reduce cost, reduce chemical needs, and increase energy savings with cyclical aerobic digestion. With the HYPERCLASSIC Mixing and Aeration System, mixing energy is dissipated at the point of air introduction, creating a surface area of constantly renewed air bubbles when air is turned on while maintaining sufficient mixing when air is turned off. This creates the ideal environment for cyclical aerobic digestion.

The system itself has a hyperboloid mixer body that is non-clogging and has integrated transport ribs for optimal fluid acceleration. There is consistent backpressure and aeration efficiency that allows for no deterioration of efficiency over time, providing the ability to turn the air on and off whenever necessary. Even with high MLSS, the HYPERCLASSIC system is robust, and also easy to maintain and operate. The system only requires above-water maintenance on the dry-mounted gear motor, and inspection on the bottom guide mounted to the floor of the tank every few years. The system is able to operate at varying water levels, with the ability to drain the tank or basin completely with no harm to the system when decanting or during the removal of the sludge. This makes the decanting process streamlined and easy due to the sludge being continuously mixed even as the water level is decreasing.

Intensive mixing is important to prevent settling on the bottom of the tank, and with poor mixing, oxygen gradients can occur. Since the mixer body of the HYPERCLASSIC Mixing and Aeration System is installed close to the bottom of the tank, oxygen gradients are prevented and a homogeneous sludge is created. Air is generated from the sparger ring underneath the mixer body. There the air escapes and meets the uniquely shaped underside of the mixer body, which is equipped with dispersing tunnels and special shear fins. As the mixer body rotates, the air in the dispersing tunnels is mixed intensively with the wastewater which creates a dissolution of coarse to fine bubbles by the shear fins. The main flow then transports these bubbles radially outwards and distributes them throughout the whole tank.

Real-world applications

With any technology, real-world applications and data show if a system works. The HYPERCLASSIC system has been installed in digesters around the world, proving to be a suitable application for cyclical aerobic digestion. In the United States, there have been multiple aerobic digestion installations with process success. The oldest running aerobic digesters with these mixing and aeration systems in the United States have been running since 2006 at the Jacksonville Beach WWTP. The aerobic digesters at Jacksonville Beach treat to 3% solids in three circular tanks and provide a consistent quality feed to their sludge dewatering process. The sludge treated continues to meet Class B standards efficiently, and the operators are very satisfied with their choice and the resulting wastewater treatment.

Another installation is across the country in Meridian, Colorado. They have an aerobic digestion lagoon system completed in 2020 with two HYPERCLASSIC systems. The operator has the ability to run them at varying water depths with ease, and there is little to no smell when standing directly over the basin. Sludge is treated to 2.5% solids at half the capacity of the previous design. This has helped decrease energy costs and increase process performance.

The cyclical process used in aerobic digestion has proven successful in both solids reduction and nitrification. The INVENT HYPERCLASSIC Mixing and Aeration System has proven suitable through real installations even at high percent solids. With the ability to cycle the air on and off while mixing, the system provides flexibility for the operator and the operation. The system's robustness and mechanical reliability make it a top choice for aerobic digesters.

Watch a video about the INVENT HYPERCLASSIC Mixing and Aeration System here