Interested in Instrumentation?

Get Instrumentation articles, news and videos right in your inbox! Sign up now.

Instrumentation + Get AlertsPretreatment turbidity monitoring is important for process control. But even the nicest looking surface water contains live microbiological particles, dissolved and suspended organic material as well as inorganic components. As any operator will tell you these stick, grow and flourish on surfaces, throughout the early phases of drinking water processing. To a lesser degree, though still an issue, films and coatings can form downstream from the finished potable water output and impact turbidity meter readings.

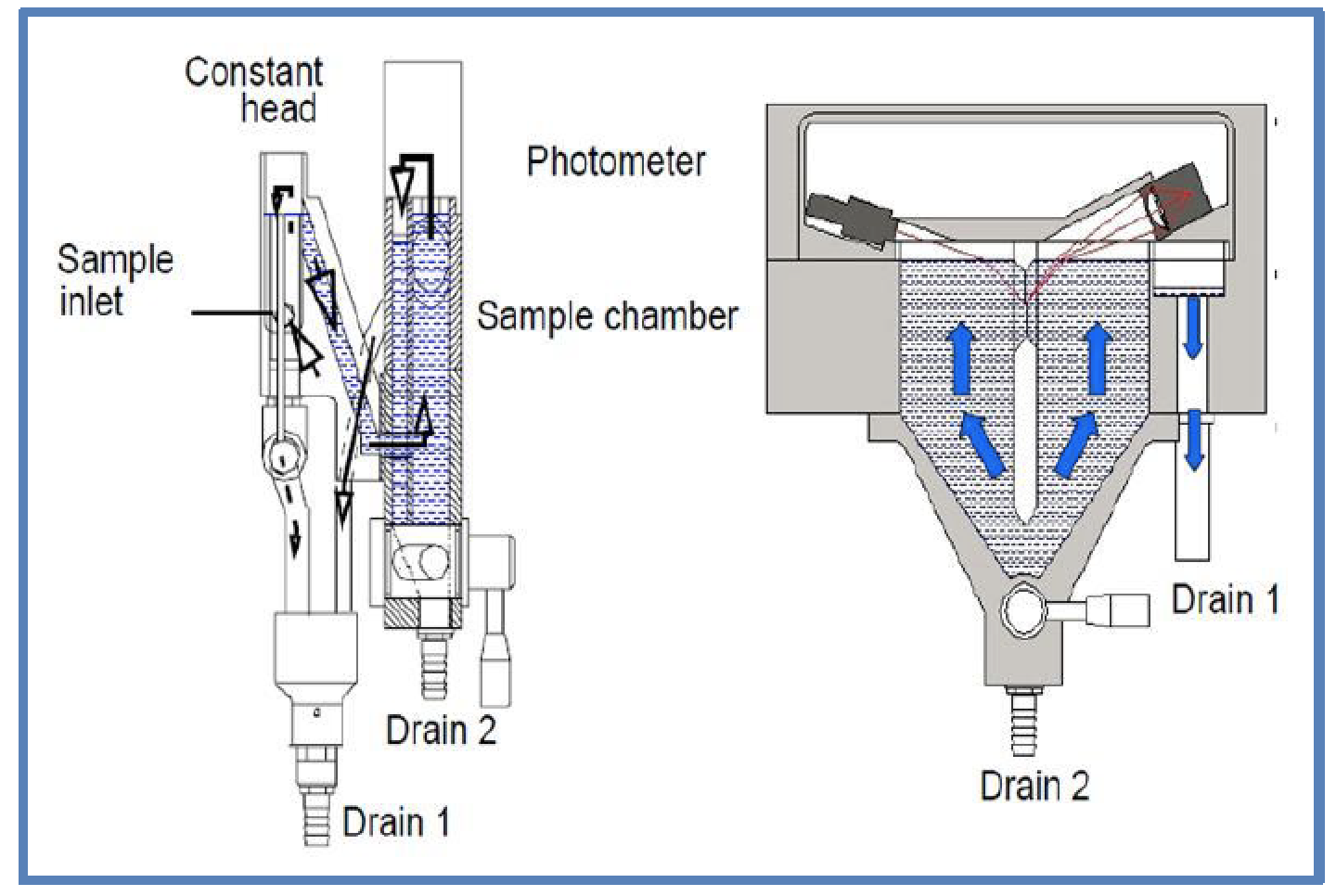

Swan has developed a method to avoid the problem of biological and nonbiological coatings and films forming on turbidity optics. This is accomplished by removing the optical source light and measuring elements from the water. Additionally, Swan optics are warmed to prevent any condensation. By keeping the optics ‘high and dry,’ the turbidity readings remain reliable for many months, often well beyond a year, and the requirement for frequent cleaning is eliminated.

Operators are required to make quarterly checks on turbidity meter accuracy and record the results and calibrations (if needed). Because of issues of optical fouling with films mentioned above, some plants make these checks as often as every two weeks. This traditionally requires making liquid formazine standards and running standards in the measuring chamber.

Swan has a solid state optical turbidity meter calibration verification device that can be used over and over and requires no preparation. In a matter of seconds it installs in the reading chamber and the operator is viewing the meter’s performance for any shift from its calibration. This simple method helps operators gain assurance of their meter’s performance and quickly indicates if liquid standards are needed for further testing and calibration. And since it is fast and reliable it is something that gets done regularly.