Interested in Instrumentation?

Get Instrumentation articles, news and videos right in your inbox! Sign up now.

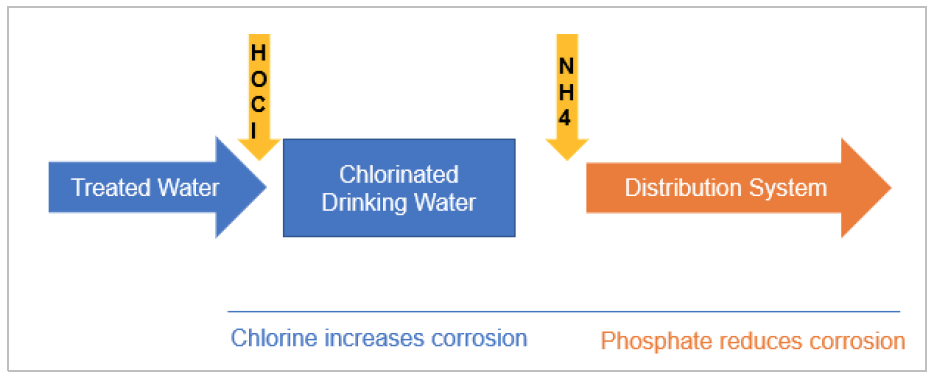

Instrumentation + Get AlertsCorrosion occurs because metals tend to oxidize when they come in contact with oxygenated water, resulting in the formation of stable metal oxides. Corrosion in water distribution systems can impact consumers’ health, costs and the aesthetics of finished water. Older systems may include lead-based solders which must be protected to avoid elevated lead concentrations which is regulated by the EPA at ≤0.015 mg/L.

Corrosion inhibitors such as inorganic phosphates in the form of polyphosphates, orthophosphates, glassy phosphates and bimetallic phosphates are often employed. To ensure proper corrosion control and the correct feed, and to reduce operating cost, reliable monitoring is required.

Phosphate is commonly used to minimize corrosion to potable water distribution systems, residential, commercial and industrial potable water piping, and reduce lead corrosion to comply with EPA standards. To achieve passivation of new or previously untreated systems phosphate is typically dosed at >3.0 mg/L as orthophosphate. The typical maintenance dosage to ensure corrosion control is 0.5-1.5 mg/L as orthophosphate.

Phosphate treatment monitoring

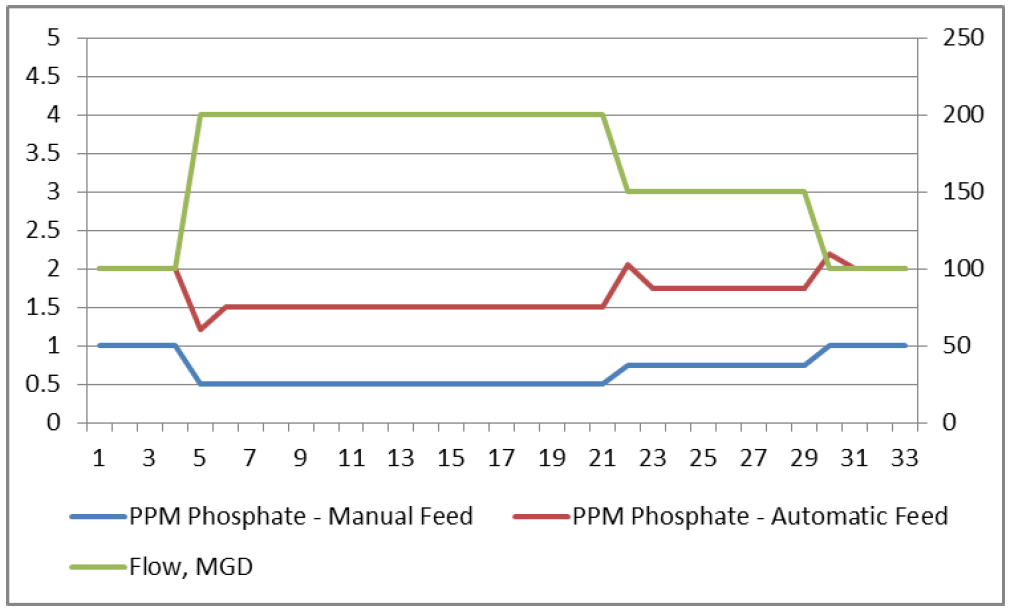

Phosphate concentration monitoring is necessary to ensure adequate corrosion control. Manual monitoring is possible, however to avoid under- or overfeed during periods of fluctuating system flows, continuous monitoring is advantageous. Controlling phosphate feed with an online instrument allows plants to minimize corrosion to meet regulatory and aesthetic requirements, and reduce chemical costs.

The above chart shows an underdosing of phosphate while the flow is increased with the previous manual feed system. Higher risk of corrosion in the distribution network and a higher concentration of lead in the drinking water are the results. A continuous system with automatic feed allows maintenance of a desired set point independent of the flow rate fluctuation.

An automatic measurement of the phosphate provides all the necessary information for proper control of the corrosion inhibitor to minimize corrosion and cost.

AMI Phosphate II

- Online analyzer for the automatic and continuous measurement of dissolved (ortho-)phosphate. Ideal to monitor and control the phosphate dosing process.

- Overflow cell and flowthrough photometer eliminates coating and clogging issues, the optional cleaning module reduces maintenance efforts.

- Built-in surveillance functions generate alarms if measurement is not valid, such as missing flow, empty reagents, valve and photometer functionality.