Interested in Treatment?

Get Treatment articles, news and videos right in your inbox! Sign up now.

Treatment + Get AlertsThe Tri-Lakes Wastewater Treatment Facility located in Monument, Colorado, receives flow from the Woodmoor, Palmer Lake, and Monument Sanitation Districts. The plant discharges treated effluent to Monument Creek, which is within the Fountain Creek Watershed. Originally, the Tri-Lakes facility consisted of a three-cell lagoon. This was replaced by a two-basin Biolac Wave-Ox system, which was installed in 1990 and later upgraded in 1998 to a three-basin system with a capacity of 4.2 mgd.

The challenge

The three sanitation districts have faced numerous challenges over the years. Growth in the surrounding communities has required expansions to manage higher flow rates. Changes to permit requirements and anticipation of future requirements have also required facility upgrades. Most recently, the Tri-Lakes facility was asked to start monitoring effluent phosphorous with the anticipation that a limit of <1.0 mg/L would be a requirement on the next permit iteration. The new permit requirements are part of Colorado’s Regulation 85 which mandates phosphorous removal.

The solution

The original Biolac Long Sludge Age Treatment System, which replaced a three-cell lagoon, was installed to achieve ammonia and nitrate removal at the facility. The system utilizes Parkson’s Wave-Ox control system where chains are grouped together, and air is alternated between groups. This creates anoxic and aerobic conditions within the same basin, so ammonia is then converted to nitrate in the aerobic zones and nitrate is converted to nitrogen gas in the anoxic zones. This allows the plant to remove total inorganic nitrogen (ammonia, nitrite, nitrate) as required by permit.

The overall treatment scheme at the Tri-Lakes WWTF consists of influent screening, grit collection, three Biolac basins with Wave-Ox controls, secondary clarifiers and UV disinfection. In 2016, the plant added a tertiary treatment step between the secondary clarifiers and the UV system to remove phosphorous in accordance with Colorado Regulation 85. The new tertiary process consists of two trains each with rapid mix tank, flocculation tank, and Meurer Research Inc. inclined plate settlers.

Aluminum sulfate (alum) and polymer are added in the rapid mix tanks which underflow into the flocculation tanks before entering the MRI plate settler clarifiers.

The results

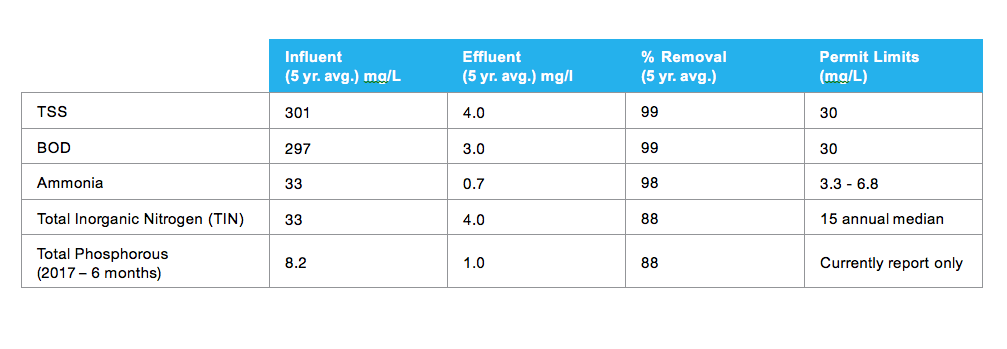

The plant has consistently out-performed permitted nutrient removal requirements, as shown in the table below. These five-year averages are based on data collected between 2013 and 2018. The plant is currently consistently achieving around 0.3 mg/L effluent phosphorous following the tertiary treatment step.

For additional information on the Biolac, visit www.parkson.com/products/biolac.

For additional information on the MRI Inclined Plate Settler, visit: www.meurerresearch.com/products/mri-inclined-plate-settlers.