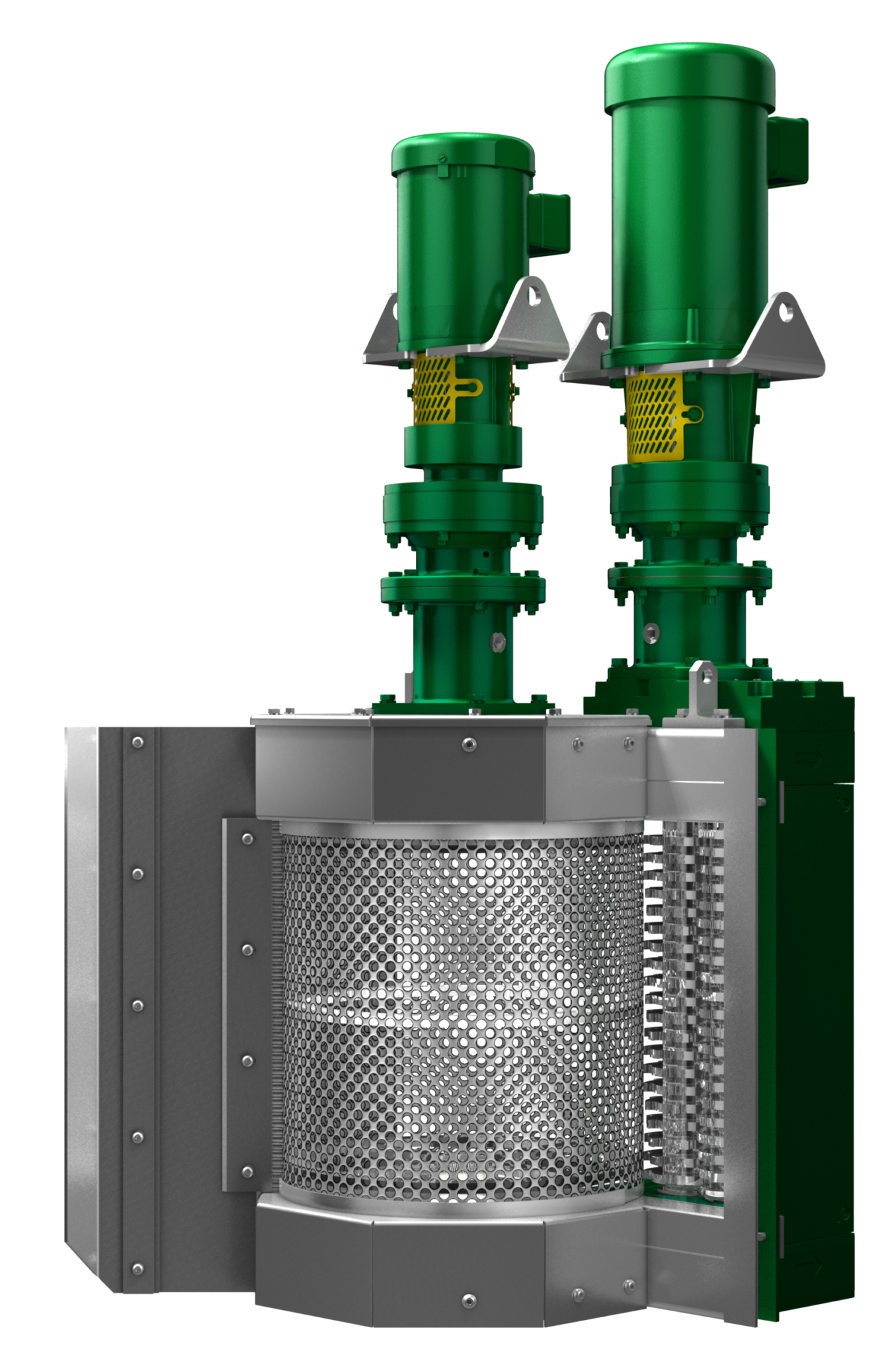

JWC Environmental unveiled the Channel Monster FLEX sewage grinder at WEFTEC 2018. The grinder is designed for high flow and easy service in the field. The unit consists of a FLEX grinder and a solids diverter...

New at WEFTEC: JWC Offers Improved Iteration of Channel Monster Grinder

Popular Stories

Discussion

Comments on this site are submitted by users and are not endorsed by nor do they reflect the views or opinions of COLE Publishing, Inc. Comments are moderated before being posted.