Interested in Pumps?

Get Pumps articles, news and videos right in your inbox! Sign up now.

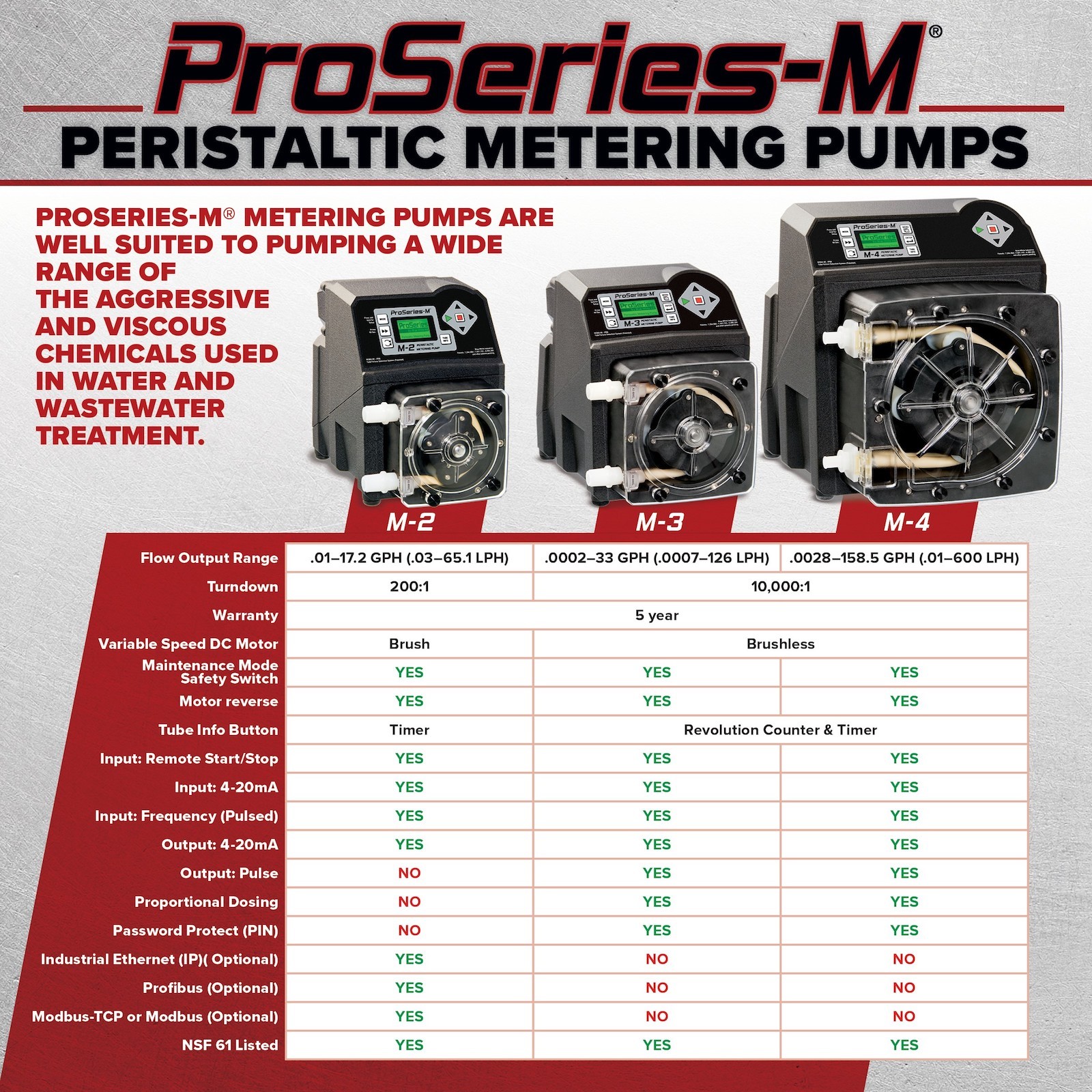

Pumps + Get AlertsBlue-White’s ProSeries-M M-2, M-3 and M-4 Peristaltic Metering Pumps have smooth, quiet pumping action and deliver precise amounts of chemical to your system. The ProSeries-M provides dependable and cost-effective service and the units are widely chosen by municipalities for the treatment of water and wastewater.

Peristaltic metering pumps can be an excellent alternative to solenoid pumps. The low-velocity injection system of peristaltic pumps provides a more gentle and efficient pumping action, eliminating the destructive forces that solenoid-type diaphragm pumps can have on piping systems. There is never a need for pulsation dampeners and expensive piping systems with peristaltic pumping units, and there are no costly rebuild kits.

Blue-White’s M-2, M-3 and M-4 pumps have been solving problems and providing solutions in many varied municipal water and wastewater treatment applications where solenoid pumps have traditionally been utilized.

A popular ski resort town located in California had been using solenoid pumps to assist with the treatment of the town’s drinking water. Sodium hypochlorite and ferric chloride needed to be injected in a multistep arsenic removal process. The off-gassing nature of the sodium hypochlorite would cause the solenoid pumps to vapor lock, so the plant switched to the M-3 pump. With no potential for vapor lock, the peristaltic design of the M-3 pump allowed the excess gas accumulation to be pumped through the tubing while maintaining smooth, accurate and constant flow rate.

Another water treatment plant in Santa Barbara County began to analyze its chlorine injection process with a system that was over 10 years old. By switching from diaphragm pumps to Proseries-M M-3 peristaltic pumps, the plant was able to reduce power consumption, simplify maintenance, increase reliability, enhance flow control, simplify the SCADA interface and remove ancillary items in their system

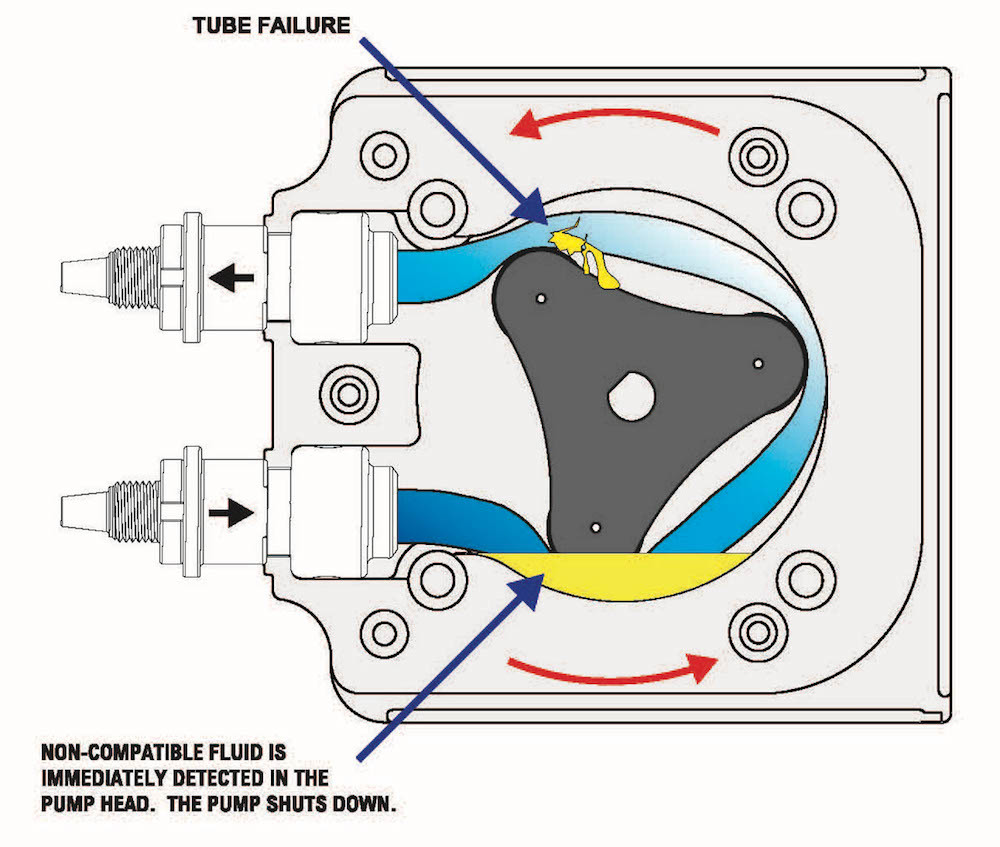

Each ProSeries-M pump has an exclusive built-in tube failure detection system. This breakthrough technology (U.S. Patent No. 7,0001,153 and 7,284,964) detects a wide range of conductive chemicals with no false triggering. This unique technology was designed to ignore pump friendly fluids, such as water and lubricants. If the TFD detects tube failure, the pump will automatically shut off and energize a relay switch. This permits communication with external equipment, such as a backup pump or alarm. The benefit of the TFD is to resolve the issue of messy chemical spills and costly clean up.

ProSeries-M offers heavy-duty pump tubing which includes multiple sizes and a variety of material options to meet a wide range of chemical compatibility requirements. The M-2 and M-3 pumps feature Blue-White’s exclusive patented Multi-Tube Technology (U.S. Patent No. 9,828,984). These innovative Multi-Tubes provide optimal performance while operating at much higher pressures than conventional single tube designs. The Multi-Tube design delivers tube life up to four times longer than average single tubes. Because of the extended tube life, pump maintenance and related costs associated with labor and parts are greatly reduced.

Multi-Tubes are equipped with clampless over molded tube fittings. The tube fittings are available with multiple connection types, including: 1/2-inch M/NPT, barb fitting and 3/8-inch tube compression, tri-clamp and quick disconnect (multiple U.S. and international patents are pending). To make part reordering quick and easy model numbers are permanently printed on the tube fittings. These model numbers are clearly visible through the pump head cover even while the pump is in operation.

Blue-White engineers designed ProSeries-M pumps to be rugged and efficient while providing precise chemical dosing. ProSeries-M units have two CNC machined rollers and two alignment rollers for optimum squeeze and tube life. The single-piece heavy-duty rotor means no flexing and increased accuracy, with no metal springs or hinges to corrode. Operators can set the pump to inject at maximum pressure in either direction, clockwise or counter clockwise.

The sturdy pump head cover is a clear acrylic that has been annealed for added strength and chemical resistance. There are no tools required for pump head cover removal, which facilitates quick and easy access during routine maintenance procedures.

The electrical interface of all three ProSeries-M pumps is an operator-friendly touchpad with menu-driven software. The VGA graphic, multicolor backlit LCD displays remote/local control status, motor speed, output rate, input signal values, service and alarm status. All electronics are easily accessible and include: Profibus, Ethernet, Profinet and Modbus. The electronics are SCADA ready and have upgradeable firmware.

To find out if Proseries-M pumps can help solve a problem or provide a solution for your company, simply contact the Blue-White sales and technical support staff. Blue-White’s worldwide network of factory authorized representatives, distributors and dealers look forward to helping you chose the right ProSeries-M pump for your specific application.

Units are NSF Standard 61, ETL, CE listed. NEMA 4X / lP66 rated.

Blue-White is ISO 9001:2015 Certified.