Interested in Treatment?

Get Treatment articles, news and videos right in your inbox! Sign up now.

Treatment + Get Alerts

Background

In August 2004, AdEdge was awarded a contract by the Black Canyon City Water Improvement District to provide a turnkey project for permitting, supplying equipment, installation, startup and commissioning of three arsenic treatment systems to bring the district into compliance with the new MCL for arsenic. The water district, serving approximately 2,500 people, uses three main water supply sources each delivering approximately 200 to 300 gpm. Treatment systems were provided at each wellhead to reduce naturally occurring arsenic ranging from 13 to 23 ppb. The district’s Water Board researched over 29 companies involved with arsenic treatment technology and chose AdEdge Technologies to complete this project based on lowest capital and operating costs, simplicity of operation, and experience in Arizona with several other successful installations.

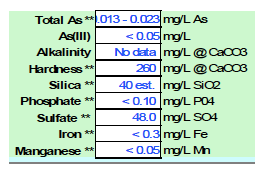

As part of the proposal process, AdEdge obtained certain site-specific design and water-quality data to form the basis of design. The table lists some of the more important water quality  parameters. The design report and permit application were submitted to the ADEQ with construction permit approvals granted in less than four weeks. The rapid turnaround by the ADEQ was attributed to the technology receiving prior approvals in the state with a similar installation in Rimrock, Arizona, under the EPA’s Arsenic Demonstration Program. Fabrication of the modular APU-300 systems commenced with site preparation tasks, which included underground piping tie-ins, concrete pads and shade structures. Equipment was then delivered and installed. These systems were the largest to date of AdEdge’s multiple installations in Arizona for public drinking water systems utilizing the granular ferric oxide technology.

parameters. The design report and permit application were submitted to the ADEQ with construction permit approvals granted in less than four weeks. The rapid turnaround by the ADEQ was attributed to the technology receiving prior approvals in the state with a similar installation in Rimrock, Arizona, under the EPA’s Arsenic Demonstration Program. Fabrication of the modular APU-300 systems commenced with site preparation tasks, which included underground piping tie-ins, concrete pads and shade structures. Equipment was then delivered and installed. These systems were the largest to date of AdEdge’s multiple installations in Arizona for public drinking water systems utilizing the granular ferric oxide technology.

System Description

Three separate APU-300 (up to 300 gpm) treatment systems were installed and deployed. Each system utilizes Bayoxide E33 granular ferric oxide adsorption media. The small footprint system features a twin vessel parallel flow configuration with automatic controls, PLC and a 100 percent backwash recycle system with zero discharge or loss of water. No pretreatment is necessary. Chlorine (sodium hypochlorite) is currently injected prior to the adsorption system for disinfection purposes. The AdEdge adsorption system requires no chemicals or regeneration, and does not generate liquid or hazardous waste. Media, when exhausted, will be discarded as a nonhazardous solid waste in a solid waste landfill. Minimal operation, maintenance or operator attention is required for this simple automated system. Instrumentation is provided on a control panel to measure critical operating parameters. Total gallon throughput and flow rate for each vessel is measured continuously with a dedicated flow totalizing meter.

Installation and startup was completed in May and June 2005, with ADEQ permit documents submitted. The permit was approved by the ADEQ and all three systems were placed into full service in October 2005. As of December 2007, treated effluent of the systems still indicate arsenic was being removed to below 10 parts per billion, exceeding predicted performance.

For more information about this and other systems, contact AdEdge Water Technologies at 678/835-0052 or visit www.adedgetechnologies.com.