Interested in Treatment?

Get Treatment articles, news and videos right in your inbox! Sign up now.

Treatment + Get Alerts

Background

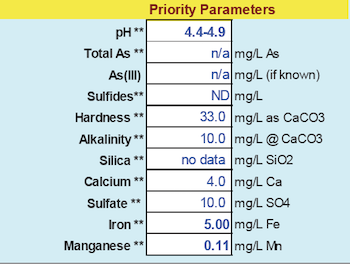

In late 2007, AdEdge began working with Maser & Associates to assist with design and implementation of an iron and manganese removal system to serve the water supply for the McGraw Hill data center in East Windsor, New Jersey. The site had an existing groundwater supply well with unacceptably high levels of iron and manganese to serve as feed water for the facilities cooling towers. The water chemistry presented some challenges with a pH of 5 and iron levels of nearly 5 mg/L. AdEdge was selected to design, build and start up an integrated treatment system to remove the iron and manganese to meet secondary MCLs of 0.3 mg/L and 0.05 mg/L respectively. AdEdge worked closely with the selected contractor Central Jersey Mechanical  to supply the treatment system which included chemical feed (chlorine and pH correction), an AdEdge AD26 packaged iron and manganese removal filtration system, treated water backwash pump skid, finished water supply booster pump package and instrumentation. AdEdge also furnished the system with a PLC communications module to interface and allow for continuous monitoring via the data center’s existing SCADA system. The system was constructed and deployed in the summer of 2008.

to supply the treatment system which included chemical feed (chlorine and pH correction), an AdEdge AD26 packaged iron and manganese removal filtration system, treated water backwash pump skid, finished water supply booster pump package and instrumentation. AdEdge also furnished the system with a PLC communications module to interface and allow for continuous monitoring via the data center’s existing SCADA system. The system was constructed and deployed in the summer of 2008.

Treatment System

The AdEdge treatment system featured a skid-mounted AD26 oxidation and filtration package unit sized for a maximum design flow rate of 130 gpm. The model AD26-3660CS-S-3-AVH utilizes AdEdge AD26 MnO2 media in a three-vessel carbon steel configuration in parallel. The system is equipped with automated control valves and harness, a central control panel with programmable logic controller and a color user interface screen. System features also include differential pressure switches, control panel and local gauges, flow sensors and totalizers, and a central hydraulic panel with sample ports for a complete functioning packaged unit. A hypochlorite feed and monitoring module and pH adjustment module using sodium hydroxide (NaOH) are also integrated into the system package. Each 36-inch-diameter treatment vessel contains approximately 20 cubic feet of AdEdge AD26 oxidation filtration media. Other ancillary equipment that was totally integrated with the treatment module included the auxiliary finished water backwash supply, distribution booster pumps, the two 5,000 gallon finished water holding tanks, and instrumentation. All of these components were integrated into the design and controlled by a single master control panel in the AD26 system.

Performance

The system was started up and commenced in July 2008. The system has a very high utilization factor, receiving water nearly 22 hours per day to meet the demand of the cooling towers. Approximately 100 to 110 gpm with high iron and manganese levels exceeding 4 mg/L and 0.1 mg/L is being consistently treated to below the treatment goals of 0.3 mg/L and 0.05 mg/L respectively. The system has experienced little to no downtime since installation.

For more information about this and other systems, contact AdEdge Water Technologies at 678/835-0052 or visit www.adedgetechnologies.com.