The CalPrex pilot ran as a 10 gpm system in the fall of 2018 at Nine Springs Treatment Plant, a 42 mgd facility in Madison, Wisconsin. The pilot was situated between the acidogenic and methanogenic digesters. CalPrex was fed with acid digest.

A Centrisys CS10-4 decanter centrifuge dewatered the feed to 20% solids, which were conveyed to a recombination tank. Centrate was dosed with calcium hydroxide, causing the precipitation brushite, a form of phosphorus. The brushite settled in a lamella clarifier. Clarifier overflow was recombined with the acid digest cake and discharged to the methanogenic digester. The settled brushite was dewatered and cake was dried as a high-quality fertilizer for a study funded by the U.S. Department of Agriculture.

Pilot results

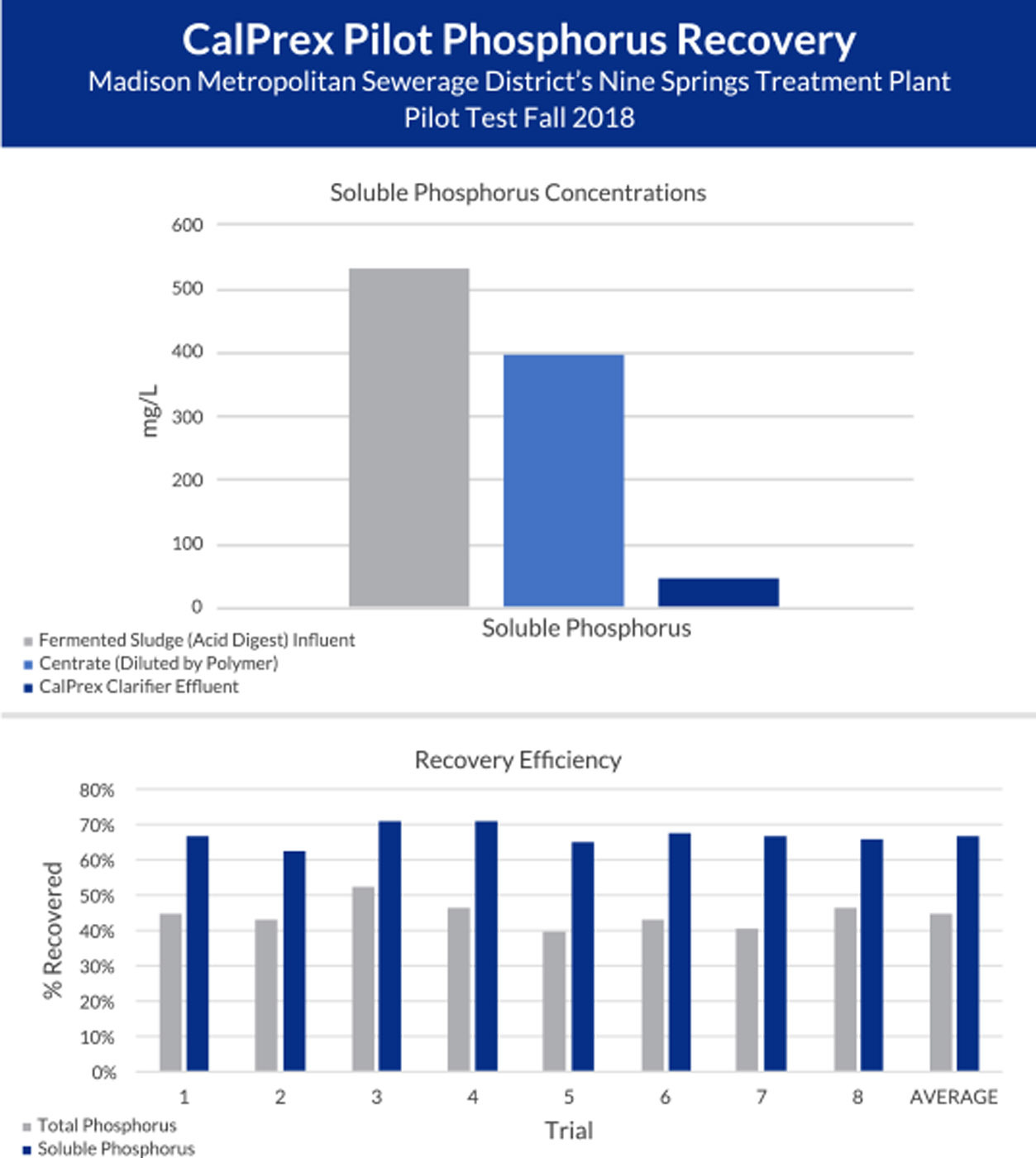

CalPrex demonstrated its ability to recover high rates of total and soluble phosphorus before the digesters. Preliminary pilot performance analysis indicates a 66% solubilization rate in the fermented sludge after the phosphorus release that went to the Ostara process in Madison.

Forty-four percent of the total phosphorus was captured with an 89% soluble phosphorus reduction in the CalPrex reactor. The pilot system’s clarifier effluent averaged 44 mg/L soluble phosphorus.

How CalPrex works

CalPrex incorporates thickened sludge from a fermentation tank or acid digester to increase the amount of soluble phosphorus which increases the phosphorus-recovery potential. CalPrex is uniquely suited for recovering a high rate of soluble phosphorus by adding calcium hydroxide without the need of ammonium.

This high-value solution is designed for facilities needing phosphorus removal and recovery prior to thermal hydrolysis; from waste activated sludge and/or primary sludge prior to anaerobic digestion; or from aerobic and post-aerobic digestion.

CalPrex is a viable solution for utilities seeking to mitigate operations and maintenance issues related to struvite scaling and poor sludge dewaterability.

The 11 organizations involved in the pilot project were the Water Research Foundation; Nine Springs Treatment Plant in Madison; Milwaukee Metropolitan Sewerage District; Metro Wastewater Reclamation District in Denver; Massachusetts Water Resources Authority in Boston; Colorado School of Mines in Golden; University of Wisconsin-Madison; Black & Veatch of Madison; Hazen and Sawyer of Virginia Beach, Virginia; Centrisys/CNP of Kenosha, Wisconsin; and Nutrient Recovery and Upcycling of Madison.

A peer-reviewed study will be published by WRF to elaborate on the CalPrex process performance, benefits, costs and larger scale impact.

Centrisys/CNP supports global sustainability through its resource intensification portfolio with water and wastewater equipment and processes. Its systems are designed for simple operation using less energy, less space and fewer chemicals. Centrisys Corp. is a U.S. manufacturer of dewatering centrifuges, sludge thickeners and complete dewatering systems for municipal and industrial water and wastewater. Centrisys’ service department is a leader in global service, repair and parts for all centrifuge brands. CNP – Technology Water and Biosolids Corp. designs and supplies nutrient-recovery and biosolids-treatment optimization systems. CNP’s key technologies are AirPrex and CalPrex, phosphorus-recovery technologies that produce struvite and brushite fertilizers, and PONDUS, a thermochemical hydrolysis process which increases biogas production and digester capacity and reduces sludge volume and polymer consumption. CNP is a U.S. distributor for digester and storage tanks and hydrograv adapt variable-inlet systems.

262-654-6006 | info@centrisys-cnp.com | www.centrisys-cnp.com