In a perfect world, the output of a pressure transmitter would vary only in response to a change in pressure input. Unfortunately, the perfect pressure transmitter has yet to be invented.

All transmitters exhibit a measurable susceptibility to ambient temperature variation. This will remain true until transmitters are constructed from materials having a thermal expansion coefficient equal to zero.

It is important — sometimes more so than others — for the transmitter user to understand the effect of ambient temperature variation on the overall accuracy. Rarely does the ambient temperature remain constant over long, and even short, periods of time, so if it can affect the accuracy of a transmitter, it behooves the user to know how, and by how much.

Expressing accuracy

The accuracy of a pressure transmitter can be expressed in many different ways. Most common is the practice of “subdividing” the sources of error into “static” and “thermal” errors. Static error — which usually includes nonlinearity, hysteresis and nonrepeatability — gets its name from the fact that it’s determined at a constant temperature, usually 25 degrees C.

It’s a good indicator of the ability of the device to accurately convert the (physical) pressure input into an (electrical) output signal, so long as the device is maintained at the reference temperature. The “thermal” error is provided to allow the user to predict what the total error might be at a temperature other than the reference temperature.

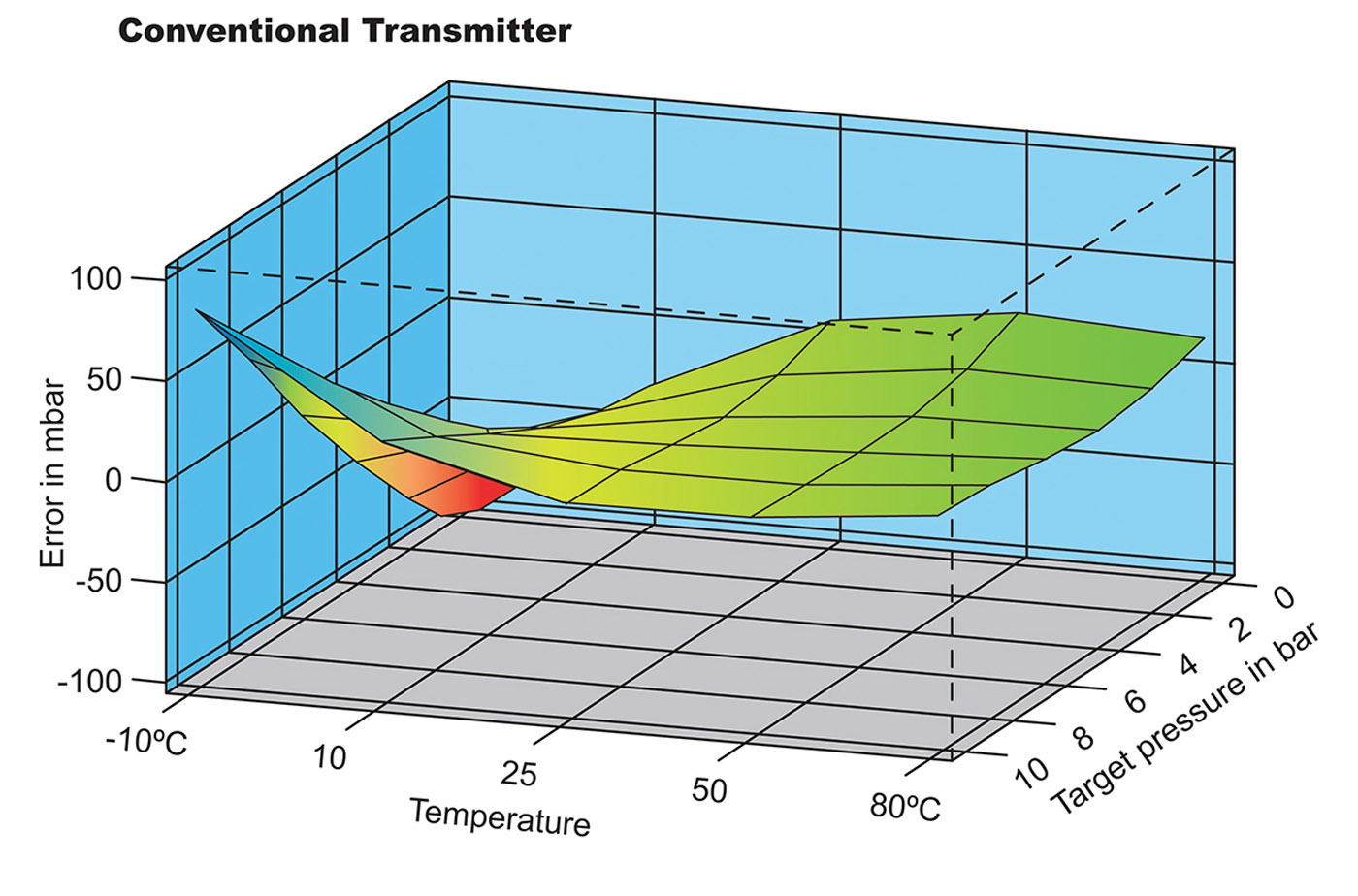

Typical test results obtained from a good, passively-compensated transmitter are shown in Figure 1.

All-inclusive error spec

Suffice it to say, the static error alone is not a good indication of the accuracy achieved in most real-world applications. What is needed is a simple-to-understand, all-inclusive error specification like Total Error Band.

The concept of Total Error Band is not new. It’s a method which combines both static and thermal error sources into one, easy-to-understand number. It is usually expressed as ±XX% of full scale, defining an error band referenced to an ideal (zero error) input/output curve. Simply stated, the transmitter output will never exceed the limits of the error band at any pressure within the rated full scale or at any temperature within the compensated temperature range.

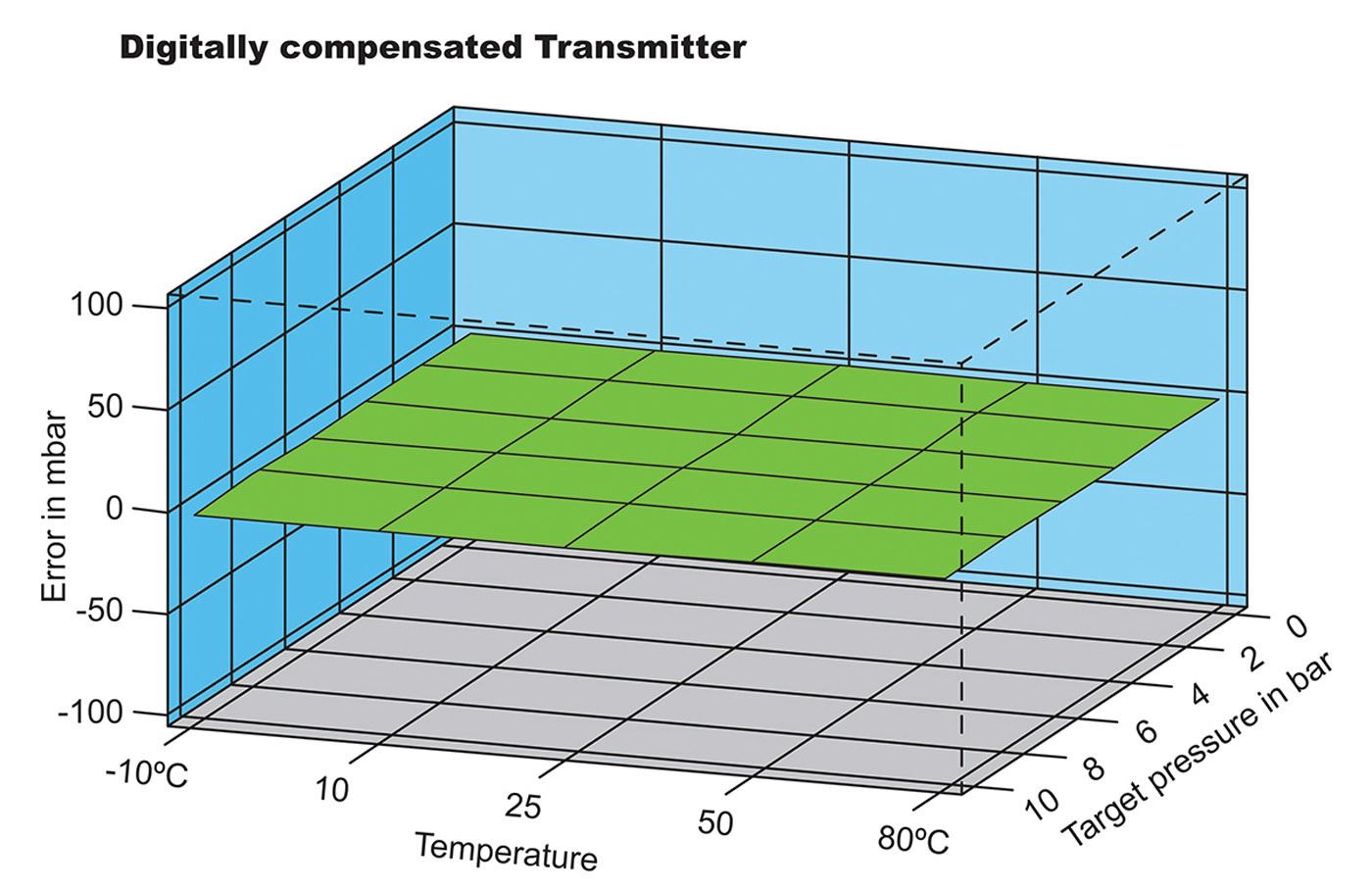

With miniature microprocessor technology and stable sensor design, this technique can be cost-effectively integrated into individual pressure transmitters. The results are fairly spectacular, as the error band is typically narrowed by a factor of 100. Sensors are married to microprocessor circuits to form a transmitter then subjected to an extensive calibration routine including a series of complete pressure calibrations at several different temperatures which collectively define the compensated temperature range.

The result is a coherent map — or mathematical model — of the transmitter in the form of polynomial equations for calculating temperature and subsequently true pressure, using coefficients stored in the on-board EEPROM. In practice, the internal microprocessor calculates the true pressure from these equations. Typical results obtained by this technique are shown in Figure 2.

If the transmitter has an analog output, this output is updated at a preset rate, typically 400 times per second. State-of-the-art transmitters will have both analog and digital — usually bus-compatible — outputs, assuring the user of the utmost in interfacing flexibility.

Keller America is a leading manufacturer of level and pressure measurement instrumentation headquartered in Newport News, Virginia.

877-253-5537 | www.kelleramerica.com