Interested in Dewatering/Biosolids?

Get Dewatering/Biosolids articles, news and videos right in your inbox! Sign up now.

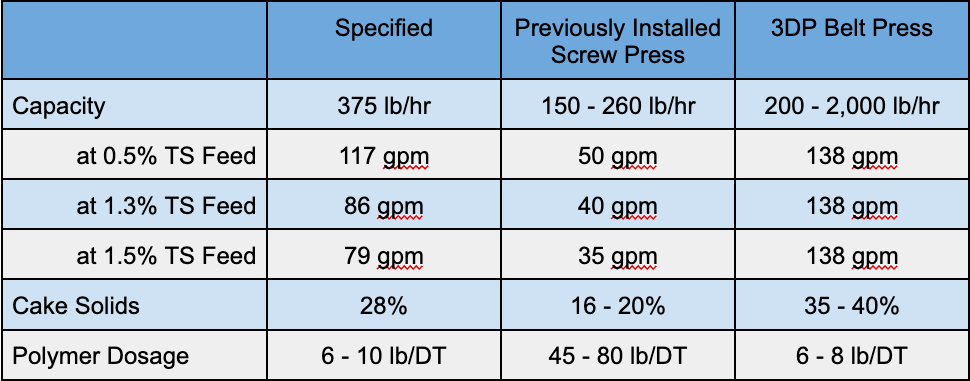

Dewatering/Biosolids + Get AlertsThe City of Ogden Water Treatment Plant struggled with solids dewatering, often operating multiple shifts and incurring high costs for polymer. In 2019, the city replaced its screw press with a 1.5 meter 3DP Belt Press. The 3DP more than doubled the capacity of the screw press, increased discharge cake solids from 20% to over 30%, increased solids capture to over 95%, reduced operating time by more than half, and reduced polymer consumption by over 80%.

“We are very satisfied with the results. We anticipate to see approximately $26,000 in savings this season on polymer usage. Not to mention a massive reduction in operating costs such as labor, etc. The belt press’ filtrate is superior to what our previous dewatering equipment could do — enhancing our pretreatment process immensely,” said Ogden Water production supervisor, Ruston Monson.

An increasing number of water treatment facilities are looking to process their residual solids on site, and are evaluating dewatering equipment and technologies. Residuals from WTPs differ in nature from solids at WWTPs and often require dewatering technologies with the features and design elements that can properly handle the WTP residuals. The three-belt filter press offers an excellent option for these facilities to consider. With its history of dewatering aggregate and minerals, as well as WWTP residuals, the belt press is able to blend the necessary dewatering features to achieve very high discharge cake solids and high solids loading rates with very low polymer dosages and very low energy usage. The use of an independent gravity belt in conjunction with a heavy-duty pressure section has proved to be a great combination for WTP facilities, allowing them to handle ranges of thin feed solids or variable solids characteristics due to fluctuations in incoming turbidity.

Visit the BDP Industries, Inc. Storefront