Interested in Instrumentation?

Get Instrumentation articles, news and videos right in your inbox! Sign up now.

Instrumentation + Get AlertsThe water district for a coastal resort community provides freshwater and sewer service to more than 40,000 residents and 2 million visitors per year. The district delivers 6 million gallons of water each day to homes and businesses and removes 4 million gallons of wastewater for treatment.

The district’s facilities cover a substantial area. The sewer system contains 125 miles of pipelines, 3,800 manholes, 14 lift stations and 3 miles of pressurized mains. The district’s commitment to quality service is evident: to meet or exceed state and federal standards through disciplined maintenance and repair, as well as the addition of capital improvements to its facilities.

The challenge

Lift Station 9 is located in the environmentally sensitive marina area of the harbor, with the pressurized main discharge manhole very near a highly used jogging and biking path. The influent for this station is primarily from restaurants and businesses in the marina. Unfortunately, many of the restaurants in the marina area are older, meaning that they do not have updated grease interceptors required of new food service establishments. The influent to the lift station, therefore, contains an inordinate amount of grease and food wastes. Rapidly decaying wastes, plus normal sewage, along with long periods of very low flow during the offseason, contribute to an environment for heavy production of liquid sulfides. Add the turbulence created as the effluent of the force main drops almost 10 feet to the floor its discharge manhole and you have the ideal situation for the release of extremely high levels of hydrogen sulfide gas (H2S). The result is both corrosive damage to the manhole cover, ring and lining, and significant odor complaints.

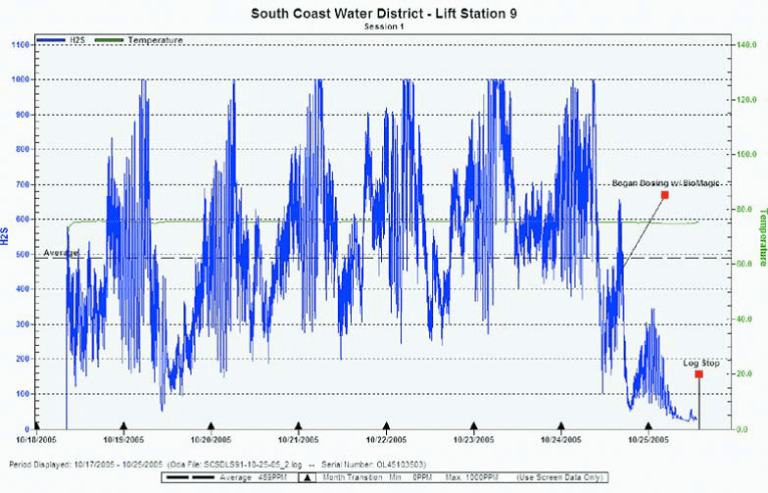

To determine the extent of the problem, baseline measurements were taken in the force main discharge manhole for one week using an OdaLog L2 H2S data logger from CAS DataLoggers. The average H2S concentration for the baseline test was 527 parts ppm, and at least once each day, H2S levels exceeded the instrument’s 1,000 ppm upper limit.

Solution

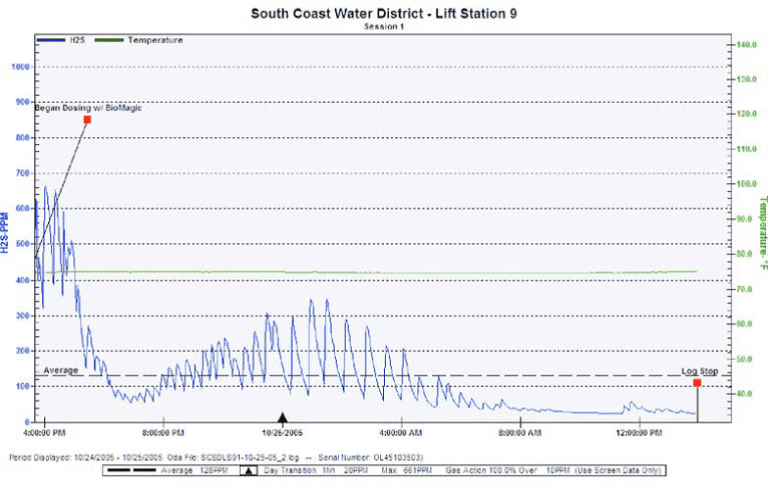

A chemical injection system was set up to deliver product directly into the wet well. Because of the extremely high sulfide levels, an aggressive dosing scheme was implemented. This dosing was semi-continuous, delivering every three minutes.

Results

H2S levels recorded by the OdaLog L2 dropped dramatically to fewer than 25 ppm during the 15 hours after treatment began — a 20-times reduction.

Dosing continued at this level for an additional 17 days while the OdaLog gas logger continued to monitor the levels. Average H2S levels were reduced even further during this time frame to 9 ppm.

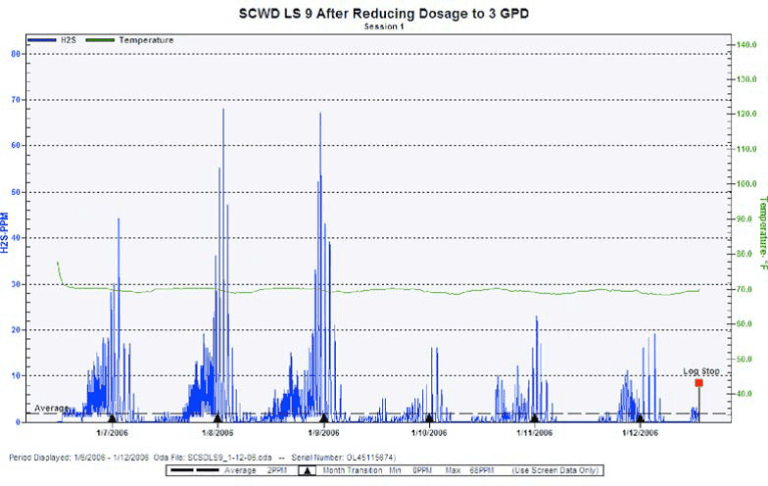

Dosing was then reduced by 40%, which was the originally agreed upon target maintenance dosing level. Treatment continued at this level for about one additional month. Testing showed that average H2S levels had dropped to 2 ppm. Toxic odor complaints had been eliminated.

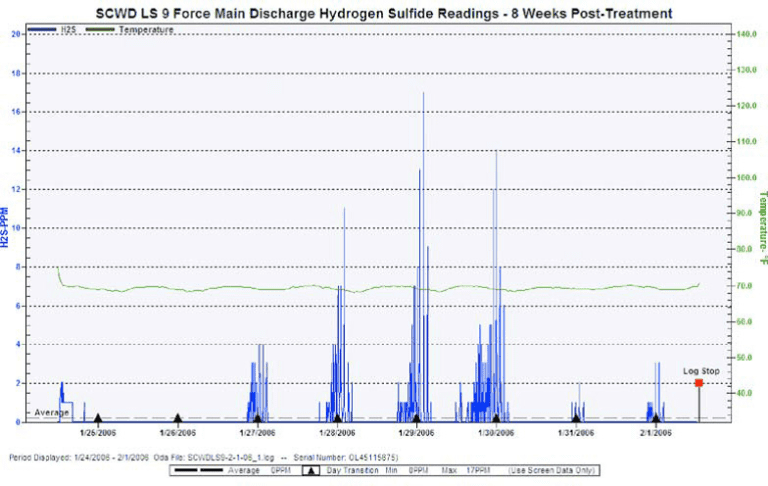

Eight weeks after initial treatment, average H2S readings were even better, having been reduced further to 0 ppm, with minor spikes of 2-15 ppm.

Toxic odor complaints have been eliminated, corrosion damage has been stopped and the district and its customers are all breathing easier. The OdaLog L2 detectors remain in place, regularly recording the H2S readings, to ensure levels are being maintained.

For more information on OdaLog data loggers, or to find the ideal solution for your application-specific needs, contact a CAS DataLogger application specialist at 800-956-4437 or request more information.