Interested in Headworks?

Get Headworks articles, news and videos right in your inbox! Sign up now.

Headworks + Get AlertsIt is relatively common to hear the phrase “resource recovery” in place of what was formerly identified as a wastewater treatment plant. Centralized wastewater treatment is essential to create safe and sanitary conditions for cities and towns. These treatment facilities have allowed for the expansion of infrastructure to accommodate growth and development.

As the concentration of people and businesses increase, so do the resource and infrastructure challenges to keep up with demand. While droughts are nothing new, large population centers are acutely susceptible to lessening water supplies. This created an impetus to investigate new water sources. Over the last several decades, advanced technologies introduced for treatment in the WWTP allowed for the possibility to extract reusable water from the waste stream.

Beyond water scarcity, increased challenges regarding the cost of energy and limited available space continue to drive innovation within the water treatment industry. Not only is water a valuable resource, but a plethora of resources can be extracted — converting wastewater from a liability to an asset. Disposal of solids in a landfill constituted a high cost and occupied dwindling landfill space. To begin with, the use of dewatering and drying technologies to process the waste sludge created a viable biosolid for agriculture land application.

Energy resources

Because the WWTP is a heavy energy consumer, the increasing cost of electrical energy helped refocus operations on improving efficiencies and what latent energy could be extracted from the waste stream. In particular, what could be extracted and put to use in the facility itself? Early on, anaerobic digestion became a source of biogas fuel that could be used for the generation of electricity with onsite biogas powered generators. This technique opened up the possibility to create enough energy to significantly offset the cost of energy required for running the treatment plant.

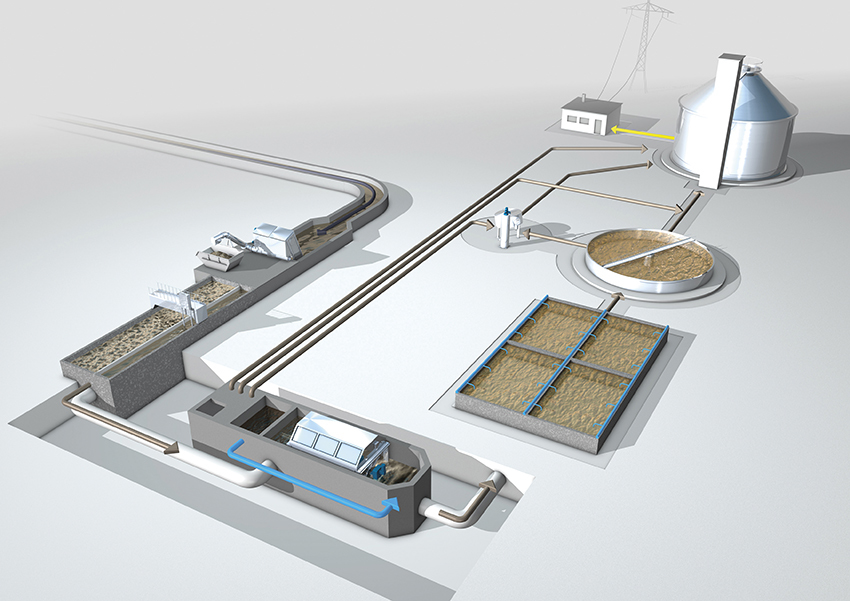

Once the digestion process was shown to be a useful energy source, seeking ways to increase production was a logical progression. Energy contained in the volatile solids content of the incoming waste stream was an identified possible energy resource. Early extraction of the solids captured by fine screens used to replace primary clarification could be redirected to the digesters. These extracted volatile solids not only increased gas production but had the additional effect of lowering the energy demand by reducing aeration requirements further in the process.

This opened up opportunities to look back into the community to seek other waste sources that could be employed for the optimized generation of biogas. Waste fats, oils and grease, once thought of as a putrid waste product, now were transformed as a viable source of energy. This also served a dual purpose, by employing a managed collection program combined with a specially designed FOG receiving station at the plant. FOG was removed as a potential liability in the standard sewer network and now was able to be directed to create energy.

Employing these techniques for comprehensive capture of usable organics for biogas production boosted the energy production. It was now possible to achieve a net zero energy consumption and, in some cases, to be a net positive energy producer.

Through continual examination of the waste stream, additional sources of energy are uncovered. The sewer network, used as a collection and transportation method, becomes a tremendous source of thermal energy for both heating and cooling. The waste stream contains latent heat energy from humans themselves. This combines with the energy that is used to heat water and is discarded into the collections system. The buried network of collections pipes beneath the various buildings provides a well-located quasigeothermal resource for heating and cooling of the surrounding structures. This technique for using wastewater as a source of heating and cooling has been successfully employed in other parts of the world for decades. Installations in North America are just now emerging.

Double-edged sword

It is interesting to note that as processes are optimized and waste is reimagined as a resource, this also serves the purpose of relieving other environmental and operational challenges as well.

Waste heat from nearby industries can be captured and reused for the drying of solids for conversion into reusable biosolids. The lower temperature thresholds of this type of dryer make it practical to locate a drying facility near an industrial waste heat source such as cogeneration plants and cement kilns. In a symbiotic relationship, the waste heat is used to dry the sludge, and the dried sludge can be used for fuel to drive the heat source.

The availability of landfills for waste disposal is rapidly getting narrower. If solids from treatment plants need to be landfilled, dewatering and drying technologies can significantly reduce the volume and weight being hauled. Similarly, technology for washing and drying grit can reduce volume by as much as half, and the quality of the product can be used as capping material for the landfill at a reduced tipping fee.

Grit slurry that is extracted by vac trucks from cleaning out sewer networks, street sweeping activities, and construction sites in the past have largely sent the captured material to decommissioned lagoons as rough fill material. In many circumstances, the previously available spaces are filling up, leaving little or no choice where to send the material.

It is possible to combine available screening and grit processing technologies into a single receiving facility. This allows for vac trucks to access a centralized depository to off-load the collected wastes. This facility can wash and classify the material into separate categories. The washed gravel and sand can be reused as roadbed material or fill for buried pipes. The separated organic materials can be classified — coarse material can be sent for composting, and the liquefied organics can be sent on to the treatment plant as additional food for biological processes.

More to be discovered

As new environmental issues rise to challenge us, once again, the treatment plant is on the vanguard of the solution. In the article “The Risks and Mitigations of Plastics in Wastewater” it was shown that a significant contributor to microplastics entering the environment was ironically the treatment plant itself. It served as a centralized point source to concentrate volumes of microplastics. This was mostly from synthetic material and clothes washing waste activities. However, by adjusting and adding treatment processes, the conventional wastewater treatment process can capture these plastics before entering the environment.

It was pointed out in “Resource Hero: The Treatment Plant Operator” that there is research unfolding that is making it practical to extract phosphorous for the conversion of usable material for agriculture. This so-called mining of the wastewater continues to open new possibilities. There is active research looking to develop practical ways of harvesting cellulose from the waste stream that can be used in construction for insulation purposes.

It seems that as the challenges in resources and the environment keep coming, the resource recovery facility (formerly known as a wastewater treatment plant) continues its metamorphosis. By demonstrating real and viable solutions, the act of treating wastes becomes an essential contributor to the solutions needed to create a sustainable environment. Activities to extract useable energy from the waste stream enables the treatment facility to offset costs and demonstrate active participation in a circular economy.

Visit the HUBER Technology, Inc. Storefront