Interested in Dewatering/Biosolids?

Get Dewatering/Biosolids articles, news and videos right in your inbox! Sign up now.

Dewatering/Biosolids + Get AlertsFeatured design/technology: Vogelsang’s InjectionSystem

Product category: Rotary lobe pumps, pump housing

Applications/industries: Pumping of any liquid, sludge, wastewater, manure, food waste, oil slurry or other liquefied waste products; a wide range of municipal and industrial applications

Design goal: Optimize a rotary lobe pump for the purposes of handling high debris or excessive solids to prevent damage to the lobes.

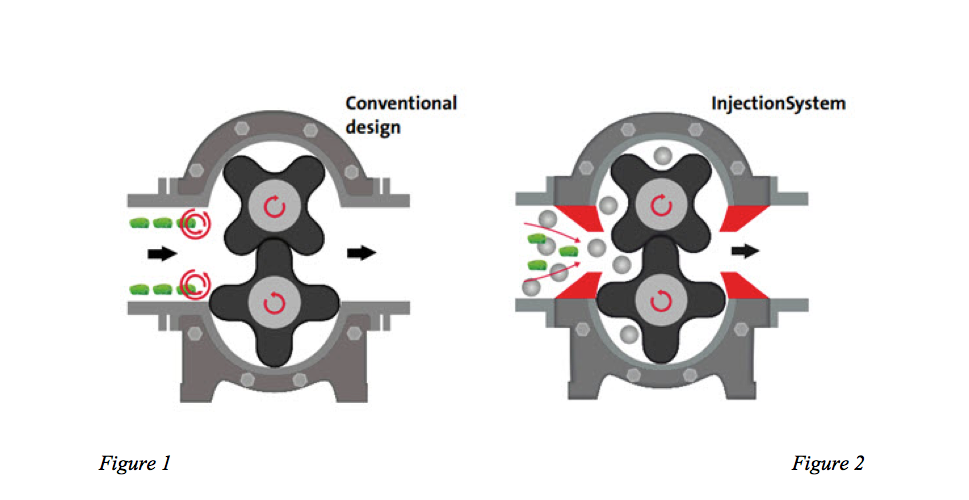

Summary of solution: The InjectionSystem is a design solution based on modifications to the housing segments without purchasing a new pump. Extended, angled tips (Figure 1, below) optimize the flow path of the pump to pass solids, while simultaneously protecting the lobe tips from being damaged by debris.

Background: Where did the idea come from? This design solution came out of a CFD flow path study and findings related to pumping liquids with a high quantity of solids. It was discovered that the traditional “straight” inlets that are used in rotary lobe pumps currently create a vortex effect that can temporarily trap material at the edge of the inlet (Figure 2). It was concluded that this vortex effect and pattern of solids being trapped can lead to increased wear to the lobe tips as the solids can become trapped between the lobe tip and the side of the housing.

What is the InjectionSystem? For a rotary lobe pump, the key design features comes in the form of housing segments with angled extensions on the suction side of the pump. These angles help optimize the flow path of the solids to prevent damage from debris contained in the liquid. See how the system works in the video below.

The design solutions

By designing the addition of angled housing, the pump’s design improved in several areas:

- Providing physical protection to the lobes and extending part life overall. The injection system both physically, and through improved suction, draws debris into the pumps solids passing cavity. This improves the flow path and greatly reduces the wear on the lobes.

- Better volumetric efficiency due to additional sealing between the lobe and housing, meaning more seal lines are used. This equates to better suction and longer wear life, even at lower pressures.

- Significantly increased operation time — up to 2.5 times longer in field trials — meaning lower operating costs overall.

Additional features

Flexibility and retrofits

The angled housing design can be manufactured into the housing segment itself or it can be added on via a small adaptor piece. This adaptor design allows for a standard housing to be retrofitted and/or changed easily in cases where a pump is repurposed.

Multiple setups

The injection design is available in two setups:

- Symmetrical or “S” design - For pumping easily flowing fluids containing small foreign matter. This design features symmetrical housing segments with the InjectionSystem design arranged on both the discharge and suction sides.

- Asymmetrical or “A” - For pumping fluids with large pieces of foreign matter, or viscous media with many pieces of foreign matter. It features asymmetrical housing segments with the InjectionSystem design arranged on the suction side.

Visit the Vogelsang Storefront