Interested in Dewatering/Biosolids?

Get Dewatering/Biosolids articles, news and videos right in your inbox! Sign up now.

Dewatering/Biosolids + Get AlertsIn the positive displacement category, rotary lobe pumps provide a compact, easy-to-maintain pumping solution that can handle a variety of applications at a wastewater treatment plant.

Vogelsang, a company responsible for some notable advancements in this technology over the past 30 years, has perfected a pump design that can handle the demands of tough wastewater sludge containing solids, abrasives and debris. But the same pump design also delivers a pulsation-free flow, making it ideal for feeding dewatering equipment such as a belt press or centrifuge. Whether you’re pumping primary or secondary sludge, WAS, TWAS, RAS or even FOG and DAF, Vogelsang rotary lobe pumps have a long history of providing reliable pumping solutions at WWTPs.

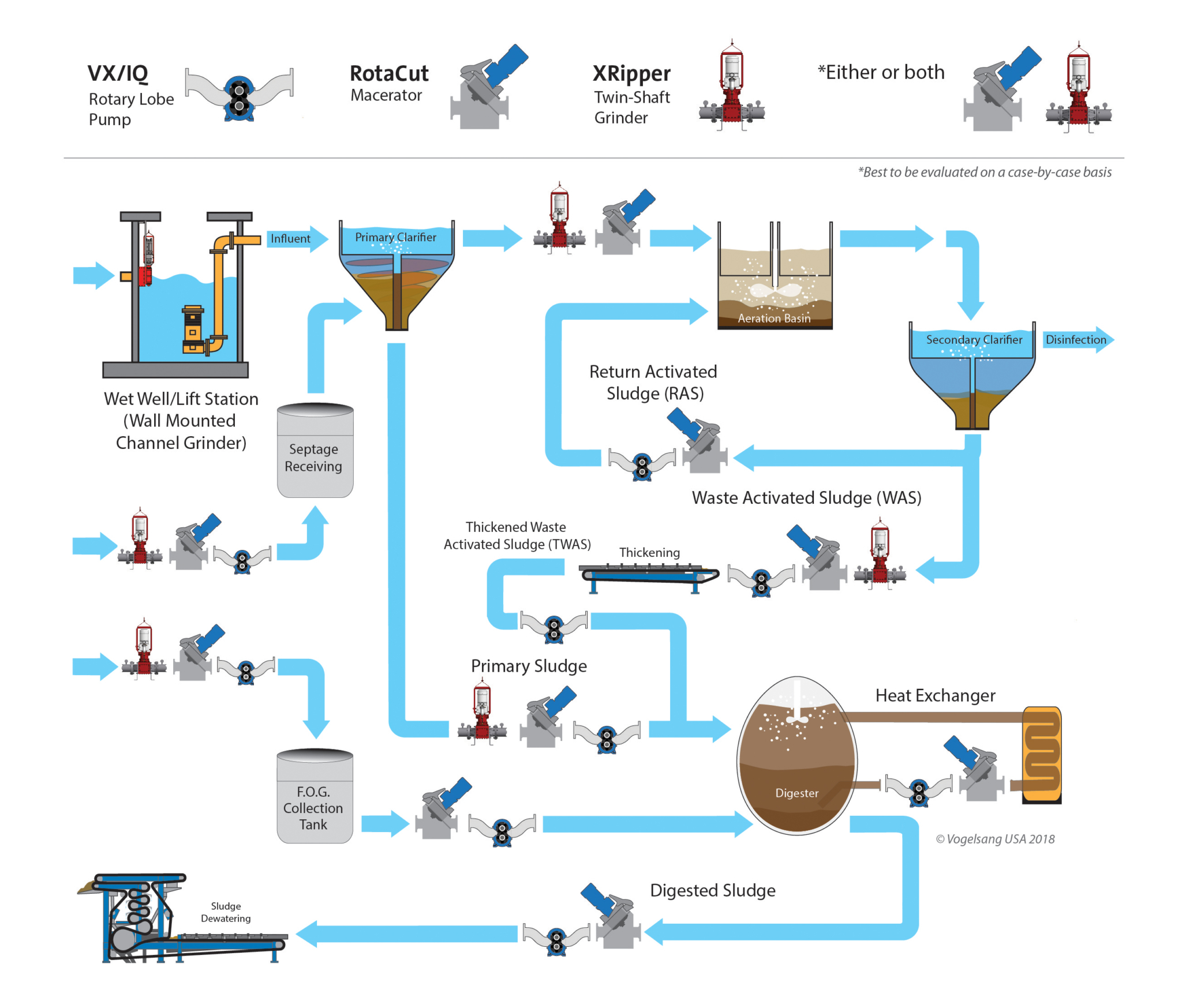

The diagram below shows common applications for Vogelsang rotary lobe pumps in wastewater treatment (alongside the company’s two main product lines for solids handling: the RotaCut Macerator and XRipper Twin-shaft Grinder.)

Download the diagram in a PDF format here.

Primary and secondary sludge are typically where we find the heaviest concentration of grit and floatable nonorganic debris in the wastewater plant. The solids content is usually low: typically, 1% to 3% solids. Vogelsang offers harder materials for the wet end along with abrasive-friendly elastomers for the lobes. Typical operation is best if the pump pulls a constant low flow of sludge versus intermittent off-on operation.

Waste activated and return activated sludge requires the ability to pump varying viscosities. WAS and RAS are typically mild because the majority of the grit has settled out. The main challenge in pumping WAS or RAS is that it often contains high amounts of entrained air, which can cause cavitation. Vogelsang gooseneck flanges keep the pump primed and avoids air locking. Standard materials of construction are sufficient for most applications, including NBR lobes and either cast iron or austempered ductile iron.

Thickened sludge pumps, TWAS pumps and digested sludge pumps — Digested and thickened sludge applications are very common in wastewater plants that use either anaerobic or aerobic digestion. These applications are normally between 3% and 8% solids with light to medium abrasive with solids such as hair and rags. Vogelsang has proven that the correct rotor elastomer is very critical for these applications. Digested sludge applications require a low-pulsation flow that is available in a Vogelsang pump when feeding dewatering equipment. The lower the pulsation, the more accurate polymer dosage can be applied.

Dewatering sludge feed pumps from Vogelsang have been widely chosen to feed dewatering equipment such as belt press, centrifuge and gravity belt thickeners. This is largely due to the pump’s ability to deliver sludge to the equipment evenly with no pulsation. An even flow of sludge to the dewatering equipment helps the equipment run as efficiently as possible and with less polymer. Additionally, it's compact and easy to fit or retrofit onto the same skid as the dewatering unit itself.

DAFT pump applications are difficult, not only because of the entrained air, but also the thickness of the sludge. Vogelsang pumps are designed for pumping viscous liquids containing heavy solids. A slower operating pump coupled with a wide range of available elastomers is critical. These applications require low speed in order to keep the pump from excess cavitation due to air pockets building in the cavities of the pump. Vogelsang pumps can handle the floating solids, hair and rags that can build up over time.

Scum, septage and FOG is usually saturated with air and loaded with inorganics (floatables). Pumping high concentrations of floatables without sufficient water to move the solids is difficult due to the lack of conveyance. Even though flows are typically pretty low, an oversized pump running slow will allow larger solids. Septage pumping can sometimes be the most difficult application in a wastewater plant, and normally ranges from 0.5% to 1% solids and contains grease, hard solids, hair, rags and other solid wastes. Vogelsang handles these challenges with ease, while providing a solution that is more cost-effective to maintain than progressing cavity pumps.

Click here to learn more about the Vogelsang family of wastewater sludge pumps and solids handling solutions.

Visit the Vogelsang Storefront