Interested in Energy?

Get Energy articles, news and videos right in your inbox! Sign up now.

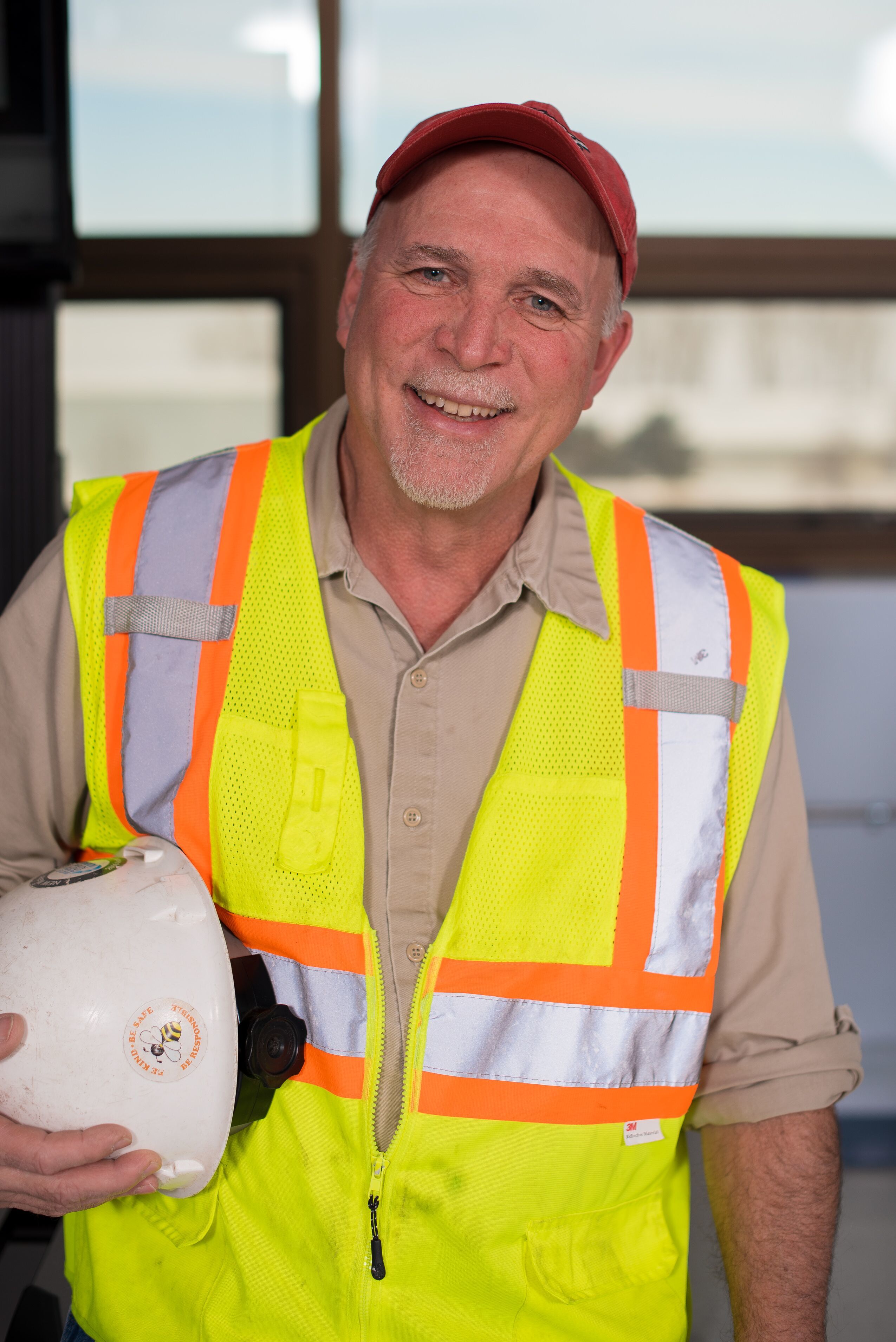

Energy + Get AlertsCraig Lawniczak graduated from high school in 1975 and wasn’t sure what to do next.

He spent the summer “sitting around” until September, when he found out the wastewater treatment plant in his hometown of Green Bay, Wisconsin, was taking applications. He recalls, “I had no experience, no background, and no reason to apply, other than it seemed like a good city job, and my dad was looking for me to find some work.”

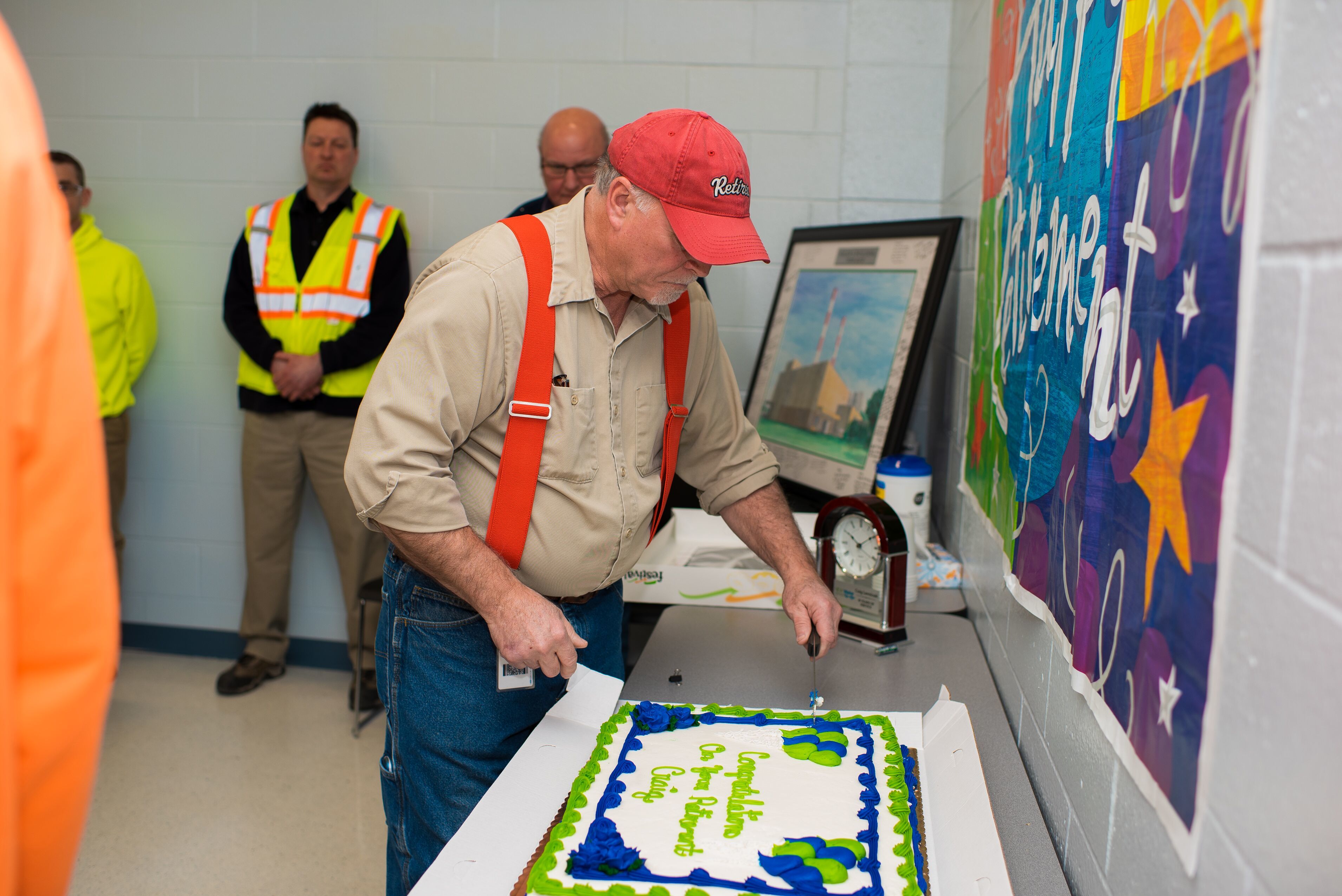

In January 1976 he was hired and went to work in a new solids processing facility. He retired March 1 of this year after leading a project to replace the facility where he started out with a new $169 million Resource Recovery and Electrical Energy (R2E2) plant.

“I went full circle,” Lawniczak says. “When I started, the solids building was brand new. My service time was the same as that building, which was commissioned in 1976. It was actually kind of hard to decommission it. A lot of me was in that building.”

Always growing

You could say there was a lot of Lawniczak throughout the Green Bay plant, now a 49 mgd (design) facility owned by NEW Water, the brand name of the Green Bay Metropolitan Sewerage District.

“When I started, the solids part of the plant hadn’t been placed online yet,” says Lawniczak, a Grade 4 wastewater operator since the late 1970s. “It was a big place to walk into as an 18-year-old kid. I definitely had the deer-in-the-headlights look.”

At the time, he was one of 44 treatment personnel: four crews each consisting of a supervisor, three foreman, six operators, and a computer operator. He was assigned to the solids operation and spent the first six months or so with a team learning how to operate the Zimpro thermal sludge conditioning process and the biosolids incinerators: “They were complex systems to learn and understand, each with large daunting control panels.”

During his second month on the job, just after he bought his first car, equipped with an automatic transmission, he had to learn to drive a standard-transmission dump truck used for biosolids hauling. “That’s another intimidating thing to learn when you’re a kid.”

In 1983 he was promoted to a process control operator position, essentially a foreman, rotating with colleagues about every three months between the incinerator, the Zimpro process and the liquid side of treatment.

Special project

In 2009, the district took over the 8 mgd wastewater treatment facility in neighboring De Pere, and Lawniczak accepted a new challenge. “We didn’t want to staff both plants,” he recalls. “I was sent over to De Pere as the operations project coordinator, upgrading that plant to be automated so we could monitor and make operational changes from the Green Bay plant.

“I was happy to take that responsibility, but it was a bit overwhelming at times. I didn’t know the plant well, but I learned it quickly. We basically had to get the existing plant equipment and some new processes talking to PLC’s so that with interplant fiber optics we could run it remotely.

In addition, the project called for interplant conveyance pipelines that traveled the seven miles transferring the De Pere biosolids to the Green Bay facility and allowing the labor-intensive De Pere solids operation to be decommissioned, says Lawniczak. “I was there for about a year and a half. The project went well, and it was a great experience.”

It was so great that when it ended he couldn’t envision going back to his previous role. “The adrenaline rush from that project was what I needed. Every day was a new adventure, and going back to just running an incinerator would have been a tough thing to do.”

A final challenge

Fortunately, at about the same time, one of the district’s three treatment leader jobs opened up, and Lawniczak was selected. At the time he thought he would hold that position until he retired. Then along came the R2E2 project, which includes anaerobic digestion for biogas production, biosolids incineration, nutrient recovery, heat capture and electric power generation. Lawniczak was named operations project coordinator.

“That was absolutely the best position to take and retire from,” he says. “It was at times an overwhelming project because of all the tie-ins we had to do to bring the old plant into the new facility. There were days when we had to do four major pipeline tie-ins. The entire electrical substation had to be replaced and relocated while maintaining plant operation.”

It was all about working with the design engineers, the general contractor and the electrical and mechanical subcontractors, he says. “It was making sure everyone was on the same page, and everything was ready to go when needed. As the workload of multiple system startups intensified, NEW Water staff members from treatment, maintenance II, and electrical and instrumentation were monumental in keeping our head above water. We referred to ourselves as the R2E2 Gang.”

The job was supposed to end in June 2018, at which time Lawnizcak was to retire, but as equipment issues emerged during startup he moved the date back. “I wanted to be there to the end of the project. I always told the operators, ‘I’ll be there until you understand how to run it,’ so I could feel good about leaving.”

Encouraging others

Lawniczak knows well that the profession needs a new generation to replace retirees like him. He believes that if young people looked closely, they would see careers that bring rewards on multiple levels.

“There wasn’t a day that I did not learn something new,” he says. “My whole career, we were adding or modifying equipment or processes. It’s constantly changing. You’re always looking for better ways to treat wastewater.”

He calls himself something of a dinosaur, having worked 43 years at a single facility. “That doesn’t often happen anymore. But today in this business you can go from one facility to another if that’s what you want to do. You can learn from each place you work at. You can start at a small plant and work your way up to a large plant.”

As the wastewater industry becomes more scientific than ever, Lawniczak says the focus of NEW Water operators will turn more toward energy management than wastewater treatment basics. “I think that is exciting,” he says.

A look back and ahead

Lawniczak’s career has been a rewarding experience, and he says he was fortunate to stumble across it so many years ago. “You always know you’re helping the environment, and that makes you feel good. It’s a stable profession. You won’t find your name on any Forbes list, but the profession provided a great living. I’d love to be an operator starting at this facility now. Making power out of waste is cool. Not that I’m ready to come out of retirement — I think I’m good with it.”

As for keeping busy in retirement: “I’ve got a 1960s kitchen that I have always promised my wife Holly we would redo after I retired. We plan to buy an RV and visit the national parks around the country, and other areas on our bucket list. I want to spend more time at our cottage and more time with family, and friends, get back into hunting, and fishing, and see if I can get back any semblance of the golf game I once had.”