Interested in Headworks?

Get Headworks articles, news and videos right in your inbox! Sign up now.

Headworks + Get AlertsPumps in lift stations require a lot of maintenance. Pumps with a large clear passage are used to prevent frequent clogging. However, those pumps have poor efficiency, particularly where the flow is low. Grinder pumps are subject to high wear, thus also requiring frequent maintenance in a narrow and dangerous environment. Pump failure can lead to back-flooding in sewer systems, sometimes causing substantial damage.

Upstream screening protects pumps from clogging and permits use of high-efficiency pumps. In addition, removal of coarse solids protects sewers by preventing deposits and reducing septicity, odor and concrete corrosion.

Huber Technology’s RoK 4 is the ideal screen for such applications. It is extremely compact and fits easily into confined spaces, such as wet wells and manholes. It vertically lifts the screenings, and dewaters and compacts them at the same time.

Features

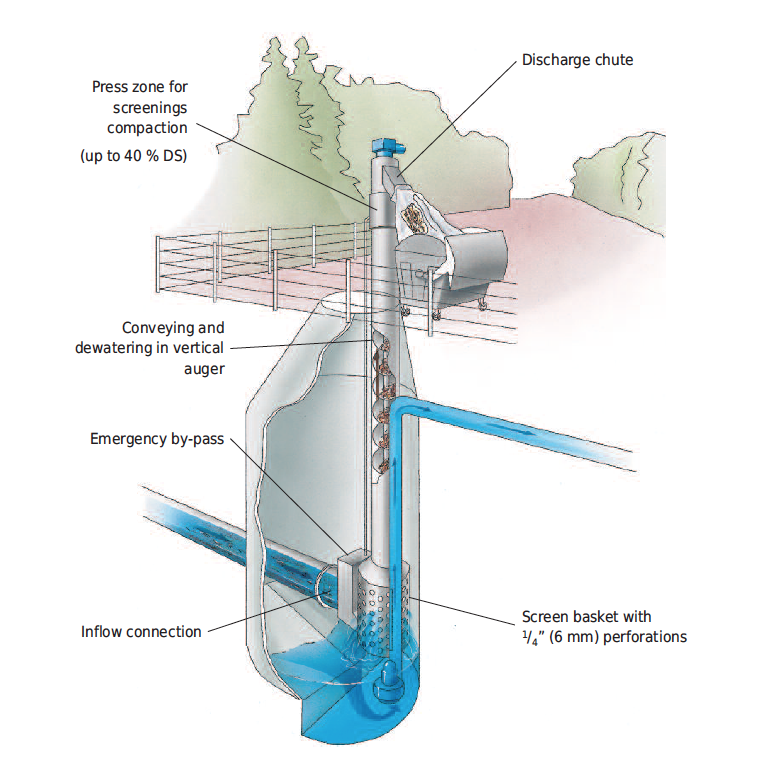

The RoK 4 consists of a vertical screen basket and a shafted auger in a vertical tube. Wastewater flows through an inflow connection and a chamber into the screen basket. The top of this chamber is open and serves as an emergency bypass, e.g. in case of power failure. The inflow drops into the screen basket thus generating turbulence for the removal of fecal matter from solids (washing action). The drop also prevents back-flooding and solids deposits in the incoming sewer.

The screen is provided with 1/4-inch perforations; other sizes are available on request. When the water level in the screen basket rises above the invert level of the inflow connection, the auger revolves for a short time period. Within the screen basket the flights of the auger are equipped with a wear-resistant brush for effective cleaning of the screen.

As the screenings are gradually elevated by the auger, they are dewatered by gravity drainage. A screenings compaction zone is provided near the upper end of the auger. Water is pressed out of the screenings through perforations in the vertical tube. Filtrate drains through a hose back into the inlet chamber. The compacted screenings are discharged through a chute into a container or endless bagger for odor control.

Benefits

- Prevents pump clogging and failure

- Screening, lifting, dewatering, compaction and bagging in a single and compact unit

- Single, easily accessible drive

- Excellent washing of fecals due to turbulent flow

- Optional frost-protection for outdoor installation

- Quick and easy installation into confined structures

- Easy retrofitting with little need for construction work

- Integrated bypass for power failure

- Sturdy design, reliable operation

- Optional guide rail for easy and safe maintenance

- Made of stainless steel, pickled in an acid bath

Applications

- Headworks of small- to medium-size wastewater treatment plants

- Pump or lift stations

- Sewer manholes or other sewer structures