CleanB operations data collected during the first full year of use confirmed projected significant reductions in energy consumption and overall operating costs.

BCR upgraded the wastewater treatment plant at the U.S. Naval Air Station (NAS) in Jacksonville, Florida, with its CleanB system, resulting in a 95 percent reduction in energy consumption for biosolids treatment and a reduction in greenhouse gas emissions of approximately 480 tons per year.

A challenging situation

NAS Jacksonville is the largest Navy base in the Southeast and the third largest in the nation. In order to meet the U.S. Navy’s aggressive energy reform targets, the base searched for efficient and environmentally sustainable technologies to reduce energy consumption.

BCR completed a detailed financial analysis based on verified operating data that compared aerobic digestion operations to the CleanB system at NAS Jacksonville. Data collected over the first full year of CleanB operations confirmed the projected significant reductions in energy consumption and overall operating costs related to biosolids treatment.

BCR delivers

The base opted to have BCR implement its recommendation — install the CleanB system into the NAS Jacksonville wastewater treatment plant. Not only did the project substantially reduce energy consumption, but it also lowered overall operating costs related to biosolids treatment by eliminating the need for aerobic digestion. BCR installed a CleanB unit to treat waste activated sludge from the clarifier to Class B standards prior to dewatering. What’s more, the CleanB solution produced a U.S. EPA-approved Class B biosolids beneficial reuse product suitable for land application.

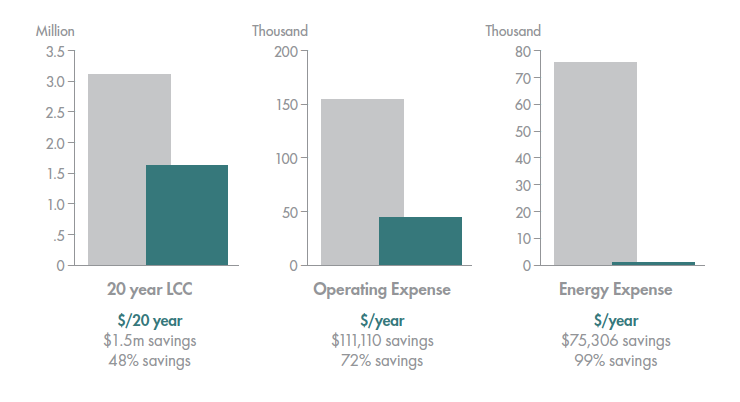

Following full-scale operation of the solution in 2012, BCR’s project delivered NAS Jacksonville the follwoing benefits:

- Energy cost savings of approximately $75,000

- 99 percent reduction in energy consumption for biosolids treatment

- Total operating cost savings of approximately $111,000

- Cumulative operating savings of approximately $2.2 million over 20 years compared with aerobic digestion operations

- Payback on equipment projected at five years (six and a half years including installation)

- Reduction in greenhouse gas emissions of approximately 480 tons and 9,653 tons over the next 20 years

- Improved dewatering of biosolids reduced total volume to eliminate 12 truckloads of biosolids, with an average annual savings in hauling and disposition costs greater than $10,000 over the project life

- 71 percent less polymer consumption

The following chart shows before-and-after 20-year life cycle costs (LCC) and before-and-after average annual operating and energy costs:

What makes BCR a trusted partner?

BCR designs, builds and assumes full project accountability for long-term, sustainable wastewater treatment/organic waste and biosolids management solutions that deliver municipalities an average savings of 40-plus percent in operating costs and 90-plus percent in energy consumption. Partnerships with BCR meet capital and operating expense constraints, assure regulatory compliance, buoy public sentiment and enhance environmental stewardship.

BCR also:

- Uses scalable, lowest-cost solutions certified by the U.S. EPA that provide high-quality end products for beneficial reuse/ land application.

- Creates economically viable solutions for <15 mgd/<15 ton per day operations.

- Provides a fully integrated platform with proven technologies and 100 percent project success.

- Delivers a progressive project delivery approach with financial and risk analysis models designed specifically for biosolids and organics operations/management.