Interested in Disinfection?

Get Disinfection articles, news and videos right in your inbox! Sign up now.

Disinfection + Get AlertsThe dissipation of ambient or process heat in large HVAC systems generated by manufacturing, power generation and food processors are often accomplished by cooling towers. These structures facilitate the transfer of heat through the use of water. The cause of inefficiencies for many cooling tower systems is fine suspended solids; they not only create an inefficient heat-transfer process but also pose a health risk. These fine solids can originate from the process, piping, atmosphere, makeup water source, and/or from the system’s internal biological growth.

During the cooling process, the cooling water absorbs large volumes of airborne particulate — acting as an air scrubber filtering the surrounding air. With time, these fine particles can build up and settle within the system, adversely affecting cooling performance while lowering the life of wetted sub-components.

Typically, 85 percent of suspended solids in cooling water and hot water loops are smaller than 5 microns in size. Scientific studies have shown that these fine particles (5 microns and less) tend to be the adherent contaminants causing fouling of the cooling tower water, chilled water and heat exchangers, thereby reducing cooling system efficiency. High volumes of fine suspended particles will not always be eliminated with the sole use of a chemical program — therefore fine filtration is becoming a vital addition.

Cleaner water in cooling & HVAC applications

Let us explore the five trends that are driving the demand for improved high efficiency submicron filtration in today’s cooling market.

- Water reuse and green initiatives — condenser and makeup water

- Data center and semiconductor demand for high-quality water

- Requirement for improved cooling efficiencies

- Requirement for reduced maintenance and operational costs

- Requirement for the creation of risk assessment programs

The cost of working with dirty water

The presence of fine suspended and dissolved solids, in high volumes, can be harmful to your cooling tower and water loop, affecting the performance of the entire system. The fine particulate under 5 microns in size aid in contributing to the following challenges:

- Component clogging, causing irregular distribution of water across the cooling tower

- Heat transfer inefficiencies, requiring increased energy and water, driving costs upward

- Scaling, fouling and bacteria growth (such as legionella), causing quick degradation of components — yielding early replacement, increased maintenance costs and health concerns

- Unscheduled shutdowns and cleaning causing increased operating costs

- Early replacement of components (valves, pumps, heat exchangers and more)

- Increased and accelerated corrosion

5 ways Evoqua’s Vortisand system can help

Let us explore how a Vortisand high-efficiency media filtration system will optimize your water treatment efforts. Traditional sand filters are limited in their technology; the lack of fine filtration with low capacities created the demand for an improved system. The Vortisand filter has been chosen by many customers around the world for its high efficiency and submicron performance, higher flow, compact design/footprint, automated operation and lower cost of operation.

High Efficiency – Submicron Performance

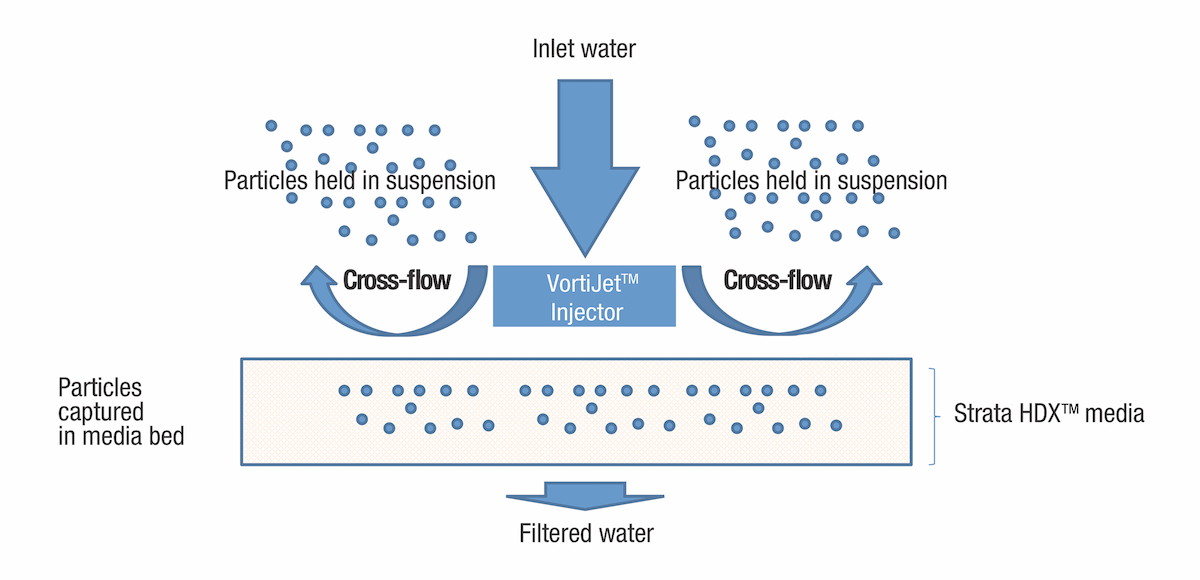

The high efficiency of the Vortisand filter lies in its unique use of microsand media coupled with cross-flow filtration, allowing the capture of particles under 1 micron in size.

Higher Flow

The cross-flow technology enables optimization of the media bed, ultimately improving filtration capacity, and allowing the design of a horizontal vessel. With a single 36-inch vessel, the horizontal design is capable of treating a flow of up to 1,090 gpm, offering unparalleled performance and value. The filtration velocity through the media bed is up to five times faster than traditional filters, at 25 gpm per square foot of filter media, while delivering higher water quality.

Lower Cost of Operation

An important consideration for any filtration system is the overall operating cost. The Vortisand filtration system potentially reduces operating costs in several ways:

- Reduced water consumption: Requires up to 50 percent less water during backwash when compared to traditional multi-media filtration systems

- Energy savings: Significant energy savings achieved in heat transfer applications by helping prevent the formation of sediment and biofilm, leading to greater heat-exchanger efficiency

- Reduced chemical costs: Significantly improve the effectiveness of chemical treatment by reducing total suspended solids

- Low maintenance costs: Requires little human intervention, with minimal maintenance tasks

Automated Operation

Evoqua’s Vortisand systems provide an automated experience, along with maintenance reminders and a user-friendly interface to ensure operating and maintaining the system is an easy task.

Compact Footprint

The effective use of microsand media ultimately results in requiring less media, enabling the system to achieve high levels of efficiency with a smaller footprint (up to 80 percent smaller and lighter in weight than traditional media filters). The system is also unique in its design, allowing for customizations to better suit the application at hand (such as a vertically stacked system capable of doubling the filtration capacity within the same footprint). The unique lightweight and compact Vortisand filter design also provides both shipping and on-site infrastructure savings.

Protect your facility, your investments and your bottom line

High-efficiency removal of fine particles and suspended solids can reduce maintenance and operating costs while improving the bottom line. A water filtration system should not be a hindrance, but instead help provide the potential to meet growing production goals, water reuse objectives and efficiencies. For more information about the Vortisand high efficiency cross-flow system, visit www.evoqua.com/en/brands/Vortisand.