For over 40 years, the Parkson DynaSand filter has been successful at continuously filtering liquid suspensions while cleaning the filter media.

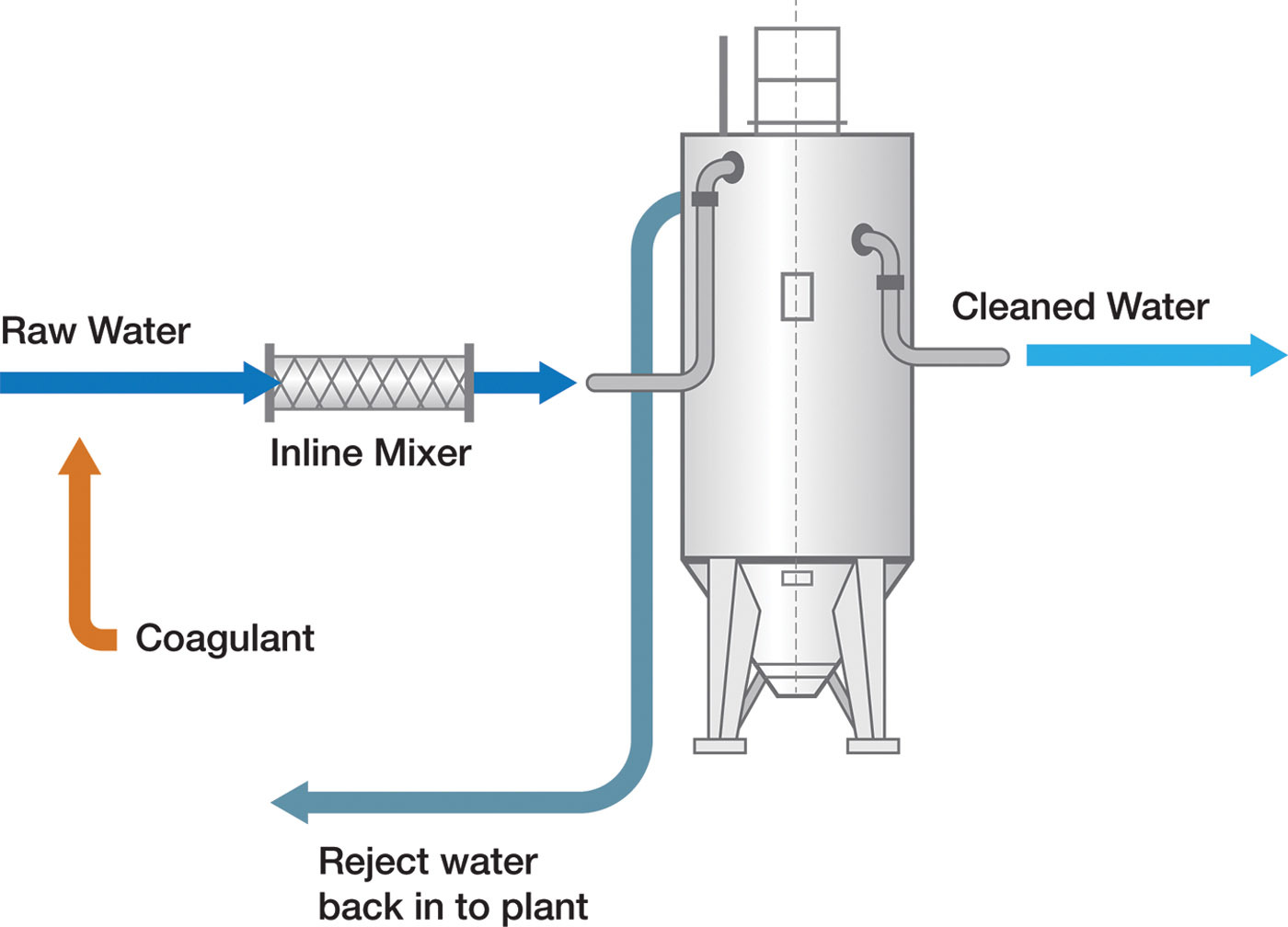

Chemical coagulants such as metal salts are injected into a static mixer in the piping prior to the filters. The effluent wastewater is then introduced to the bottom of the sand bed where flocculation takes place. This process is known as “continuous contact filtration.”

Space savings

The DynaSand filter makes it possible to carry out coagulation, flocculation and separation directly in the filter bed. This eliminates flocculation, settling and backwash water tanks, and reduces equipment volume by as much as 85% when compared to conventional chemical treatment.

Chemical savings

Coagulation and flocculation in a granular bed is an effective process, according to the manufacturer. The water to be treated will be exposed to frequent contacts with already separated flocs in the sand bed, creating many collision possibilities.

Effective separation in a sand filter can be achieved at a smaller floc size. The amount of chemical addition required is proportional to the feed flow and reduces the chemical dosage required, in some cases up to 30%, according to a Parkson spokesperson.

Meanwhile, suspended solids content can be reduced by up to 97%-98%. Excellent results are also obtained in phosphorus reduction, as several plants have achieved effluent total phosphorus concentrations of 0.02 ppm, according to the manufacturer.

Parkson is a supplier of equipment and solutions for potable water, process water, and industrial and municipal wastewater applications. Parkson designs, engineers and assembles products that provide customers with advanced screening, biological, filtration and biosolids management solutions.

1-888-PARKSON | technology@parkson.com | www.parkson.com