Interested in Dewatering/Biosolids?

Get Dewatering/Biosolids articles, news and videos right in your inbox! Sign up now.

Dewatering/Biosolids + Get AlertsIn February 2014, the City of Columbia, South Carolina received bids from three suppliers for the delivery of magnesium hydroxide to the Metropolitan Wastewater Treatment Plant (Metro WWTP) for alkalinity addition in Liquid Treatment Train 2 to ensure complete nitrification.

The city awarded the contract to the lowest responsible bidder, Premier Magnesia. A competitor protested the bid on the premise that their cost was lower and that they met the majority of the requirements of the technical specifications. The competitor agreed to rescind the bid protest in exchange for the opportunity to conduct a product demonstration test. Hazen and Sawyer was tasked with developing and implementing a testing protocol. This technical memorandum summarizes the results of the laboratory bench scale and full-scale field demonstration tests.

Laboratory Bench Scale Tests

Results of the bench scale jar tests were inconclusive. Accurate dosing of magnesium hydroxide solution could not be confirmed for the low volumes required by jar testing. Uniform distribution of solids in the diluted magnesium hydroxide solution could not be confirmed due to the lack of solution transparency. Quantitative analysis must be observed through full scale testing.

Full-Scale Field Demonstration Tests

Full-scale field demonstration testing of each product included the following requirements:

- 30-day test period for alkalinity supplementation

- Product dosed to provide a residual alkalinity of 40 to 50 mg/L at the effluent of the aeration basin

- Alkalinity monitored four times throughout the day with test strips for process control.

- Primary and secondary effluent composite samples collected and analyzed for ammonia, nitrate and alkalinity

Thioguard’s average feed rate over the 30-day test period was 900 gpd for a plant flow of approximately 11 mgd, yielding a typical magnesium hydroxide dose of 80 mg/L to achieve a secondary clarifier effluent alkalinity concentration of 40 to 50 mg/L. The competing product had numerous operational challenges and excessive dosage requirements, which impacted performance and could not be further evaluated quantitatively. The manufacturer voluntarily withdrew from the product trial.

In addition to the operational challenges the competitor’s product presented, the feed rate was in excess of three times the Premier product’s feed rate and still was not able to meet the target required alkalinity.

Recommendations

The full-scale field demonstration test indicates acceptable performance of Thioguard. The Premier product had a typical dose of 80 mg/L that resulted in an average of approximately 520 pounds/mg alkalinity addition to the Train 2 liquid treatment process.

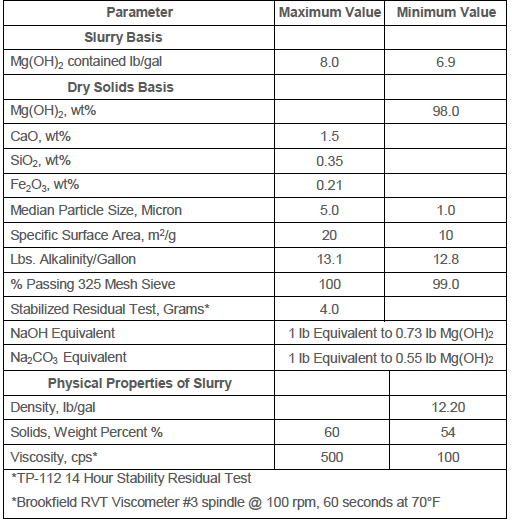

Based upon the successful results of the Premier Magnesia product, the magnesium hydroxide solution for supplemental alkalinity shall be produced and manufactured from seawater or magnesium chloride brine utilizing a wet milling process for consistent product sizing and uniformity conforming to the following chemical specifications: